In the world of industrial piping systems, forged fittings play an essential role. These fittings are crafted from high-quality materials. They are designed for strength and durability. As industries evolve, so do the trends surrounding forged fittings.

The year 2026 is expected to see significant advancements in this field. Innovative designs and improved manufacturing processes may enhance performance. However, some challenges persist. Not all manufacturers can meet the rising demands. Quality assurance remains a concern for many users.

Understanding key trends is crucial for industry professionals. Questions often arise regarding the best practices and future directions. By examining these developments, we can navigate the complexities of forged fittings. It's important to stay informed and adapt to changes for optimal results.

The forged fittings market is entering a transformative phase leading up to 2026. Analysts expect a compound annual growth rate (CAGR) of approximately 5.2% during this period. This growth is driven by increased demand in industries such as oil and gas, plumbing, and construction. The global market for forged fittings is projected to reach over $10 billion by 2026.

Technological advancements play a crucial role in shaping these trends. Innovative manufacturing techniques are enhancing the quality and efficiency of forged fittings. However, the industry faces challenges related to high production costs and fluctuating raw material prices. For example, steel prices can vary significantly, impacting overall profitability. Companies must find a balance between quality and cost-effectiveness.

Market research indicates that North America and Asia Pacific will be key players in this sector. The focus on infrastructure projects in developing regions drives demand for reliable fittings. Moreover, sustainability is becoming increasingly important. Businesses are being urged to adopt greener practices, which could reshape manufacturing standards. As these dynamics unfold, continuous reflection on strategies and operational practices will be necessary for success.

The forged fittings manufacturing sector is evolving rapidly. Innovations are emerging to enhance efficiency and quality. For instance, advanced metallurgy techniques allow for stronger materials. This could lead to fittings that withstand higher pressures and temperatures. Manufacturers are experimenting with heat treatment processes. These processes can improve ductility without sacrificing strength.

Moreover, automation is becoming a key player in production lines. Automated machines reduce human error, allowing for more precise fittings. However, some workers fear job security with increased automation. This perspective raises questions about balancing technology with employment.

Sustainability is also gaining attention. Many manufacturers are researching eco-friendly materials. The aim is to reduce environmental impact during production. Yet, the challenge remains in ensuring these materials meet rigorous industry standards. This highlights the ongoing need for innovation while considering quality and environmental responsibility. The journey ahead isn't perfect, but it’s full of potential.

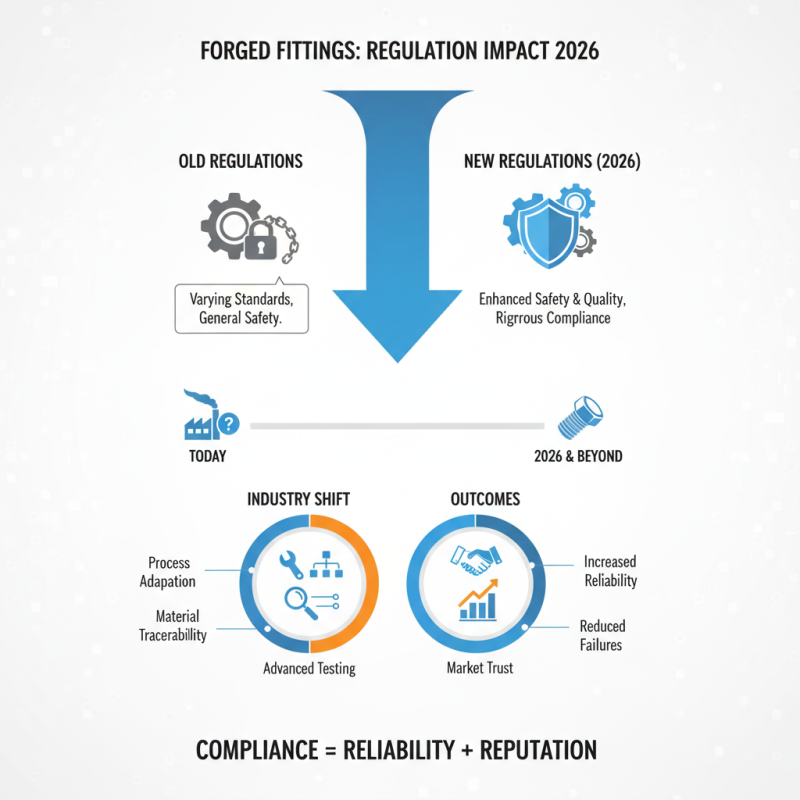

The impact of industry regulations on forged fittings trends by 2026 is significant. Regulations are evolving to strengthen safety and quality standards. This shift drives manufacturers to adapt their processes accordingly. Compliance with these regulations is not just about avoiding penalties; it's also about ensuring product reliability.

Manufacturers are integrating technology and innovation to meet these demands. Advanced materials and production techniques are being explored. However, not all companies are keeping pace with these changes. Some are struggling to implement necessary adjustments. This highlights a critical need for continuous education and training within the industry.

As regulations tighten, the emphasis on environmental sustainability grows. Companies are now more accountable for their environmental footprint. This focus presents both challenges and opportunities. Forged fittings must evolve to align with sustainable practices. Yet, some manufacturers may resist these changes, fearing increased costs. This ongoing tension will shape the market landscape leading up to 2026.

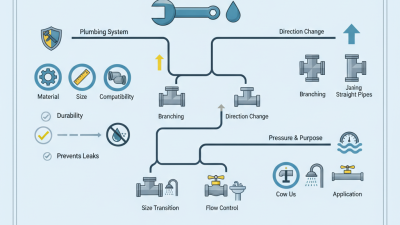

Forged fittings are vital in many industrial applications. They provide robust connections in piping systems across various sectors. Questions about their properties and uses often arise. Understanding these aspects is crucial for engineers and procurement professionals.

One common inquiry is about the material strength of forged fittings. Studies indicate that carbon steel fittings possess a tensile strength of up to 70,000 psi. This high strength allows them to perform well under pressure. However, it is essential to evaluate the specific requirements of each application. Not all projects need such high strength. This could lead to overspending if not carefully assessed.

Another frequent question concerns the temperature limits of these fittings. Forged fittings typically handle temperatures ranging from -50°F to 800°F. However, some environments may push these limits. It is essential to conduct proper assessments. Some users have reported failures in extreme conditions. Industry reports suggest that 15% of installations fail due to improper fitting usage. Awareness of these risks is key. Making informed decisions can enhance safety and efficiency in operations.

Choosing the right forged fittings is crucial for various industries. The materials and specifications required can vary greatly. Factors such as pressure, temperature, and the nature of the fluid being transported play critical roles in this decision.

For the oil and gas sector, high-temperature fittings are often necessary. They must withstand extreme conditions. Consider how contaminants can affect your selection. Regular inspections can prevent failures. Also, remember that each application may require unique fittings.

Tips: Always consult with industry experts. They can offer insights tailored to your specific needs. Pay attention to industry standards. Ensure your fittings meet safety regulations. When in doubt, re-evaluate your options. It’s better to take time now than face issues later.