When selecting the best forged pipe fittings for your projects, quality is paramount. These fittings play a crucial role in ensuring the reliability and safety of pipelines. Forged pipe fittings are designed for high-pressure applications, making their quality even more critical.

It's essential to consider various factors when choosing these fittings. Material selection is one such factor. Different materials provide different levels of strength and corrosion resistance. The manufacturing process can also impact the durability of forged pipe fittings. Knowing how they are made will help you make informed choices.

In addition, it's important to acknowledge the common pitfalls. Many people overlook details such as dimensions and pressure ratings. Often, they assume all products meet the same standards, which is untrue. By understanding these challenges, you can select the right forged pipe fittings for your needs. Quality shouldn't just be an assumption; it should be a priority.

Forged pipe fittings play a critical role in various industries. Understanding key terminology is essential for ensuring quality and performance. These components are typically made from high-quality steel, providing enhanced strength and durability. According to the American Society for Testing and Materials (ASTM), forged fittings can withstand higher pressures compared to cast fittings. This makes them suitable for demanding applications.

Key terms include “socket weld” and “butt weld” fittings. Socket weld fittings are advantageous for smaller pipe sizes. They are easy to install and provide a smooth internal surface. On the other hand, butt weld fittings are often used for larger pipes, offering excellent structural integrity. Industry reports suggest that weld strength contributes to the overall reliability of piping systems. However, the fitting must be chosen wisely based on specific conditions to ensure optimal performance.

Another important term is “pressure rating.” This rating indicates the maximum pressure the fitting can handle. As data indicates, many failures happen due to improper selection based on this rating. It is crucial to assess your operational settings carefully. Also, keep in mind that not all forged fittings are created equal. Different manufacturing processes can yield varying quality levels, leading to potential weaknesses in critical applications. Understanding these terms can significantly impact your project's success.

When considering forged pipe fittings, quality is paramount. Several factors influence this quality. One major factor is the material used. High-quality steel or alloy enhances durability. However, not all materials are suitable for every application. Choosing the wrong one can lead to failures.

Another important aspect is the manufacturing process. Precision in forging ensures proper shape and dimensions. Any misalignment during the process can weaken the fitting. Additionally, heat treatment plays a critical role. Insufficient treatment may lead to brittleness, affecting performance.

Inspection and testing are crucial but often overlooked. Regular quality checks can catch defects early. Yet, many manufacturers skip this step to save time. Ignoring this can result in costly repairs later. Adequate attention to these details ensures the long-term reliability of forged pipe fittings.

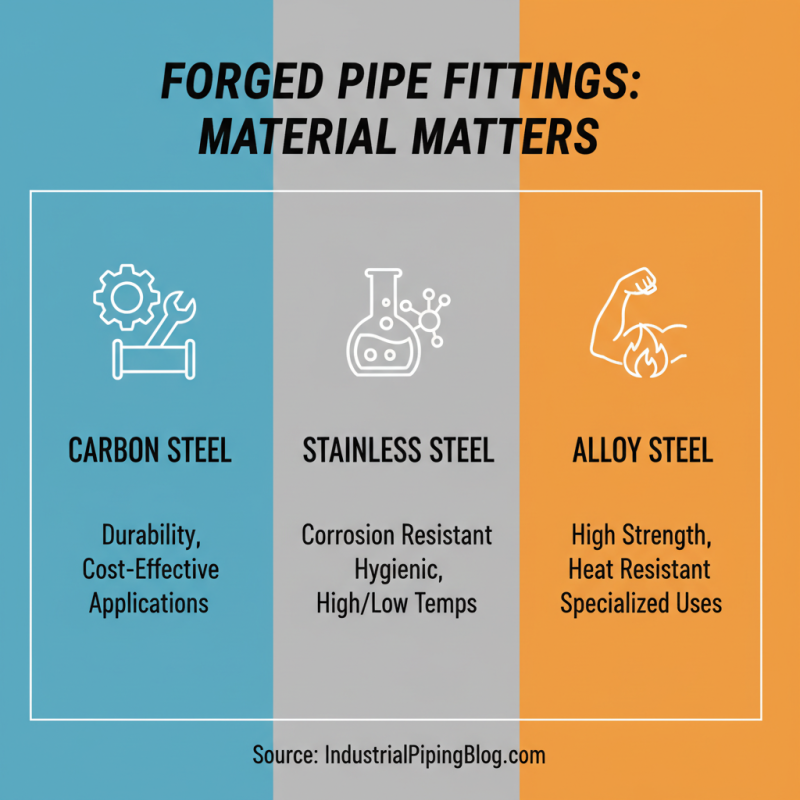

Choosing the right material for forged pipe fittings is crucial. Various materials offer different benefits and drawbacks. Common choices include carbon steel, stainless steel, and alloy steel. Each material has unique properties that affect durability, corrosion resistance, and strength.

Carbon steel is often favored for its strength and affordability. However, it can rust without proper coatings. Stainless steel, while more expensive, provides excellent corrosion resistance. It works well in harsh environments but can be prone to pitting. Alloy steel is another good option, known for its toughness, yet it can be heavy and difficult to work with.

It's essential to analyze the specific application requirements. Factors like temperature, pressure, and exposure to chemicals play a role. Sometimes, the selection process can be flawed; overlooking minor details can lead to failures. A thoughtful approach to material selection can prevent costly mistakes in the long run. Choosing material wisely is key in achieving quality in forged pipe fittings.

When evaluating forged pipe fittings, the manufacturing process plays a pivotal role in determining quality. It's essential to recognize that not all processes yield the same results. Some methods may overlook critical aspects of durability. This can lead to premature failures in demanding applications. Ensuring the right manufacturing process is a backbone for performance.

Forged fittings typically use high temperatures and pressures to shape the metal. This method enhances strength but requires precise control. Any lapses can compromise integrity. Additionally, the quality of raw materials impacts the end product. Inferior materials can lead to cracks and weak points. Sometimes, manufacturers take shortcuts, sacrificing quality for cost savings. This approach often yields products that don't meet industry standards.

Quality control measures are vital throughout production. Regular testing can identify flaws early. Yet, some companies might skip these checks for efficiency. This can result in products that fail under stress. Manufacturers must prioritize rigorous testing to ensure longevity and reliability. The focus should always be on creating fittings that withstand the rigors of their intended use. Quality isn’t just a goal; it’s a continuous commitment to improvement.

When considering the quality of forged pipe fittings, understanding the relevant quality standards and certifications is essential. These guidelines ensure that products stand up to rigorous demands. Two significant standards to look out for are ASTM and ASME. They outline testing methods and performance criteria. Meeting these standards is not just ideal; it’s vital for safety.

Another important aspect is certification. Certifications from recognized agencies demonstrate compliance with international benchmarks. Products certified by organizations, like ISO, ensure a consistent manufacturing process. This can often mean the difference between failure and success in critical applications.

It’s also worth noting that not all manufacturers may fully adhere to these standards. There can be inconsistencies in material quality or production techniques. Buyers should always verify certifications and request supporting documentation. Inspecting samples can reveal hidden flaws. Relying solely on claims without due diligence can be risky. Understanding these aspects enables informed decision-making in the selection of forged pipe fittings.

| Specification | Material | Pressure Rating | Standards | Certifications |

|---|---|---|---|---|

| 1/2" NPT | Carbon Steel | 3000 PSI | ASTM A105 | ISO 9001 |

| 3/4" NPT | Stainless Steel | 1500 PSI | ASTM A182 | API 6A |

| 1" NPT | Alloy Steel | 6000 PSI | ASTM A234 | CE Marking |

| 1-2" NPT | Forged Steel | 9000 PSI | ASTM A105N | ASME B16.11 |

| 2" NPT | Carbon Steel | 1500 PSI | A105/A105M | ISO 14001 |