In the realm of plumbing, the efficiency and reliability of our systems often hinge on the expertise of service valves. These critical components not only regulate water flow but also provide essential control for maintenance and repairs. Plumbing industry expert John Doe, a seasoned engineer with over two decades of experience, emphasizes the significance of selecting the right service valves: "The right service valve is not just an accessory; it's a necessity for optimal plumbing performance."

As homeowners and professionals alike strive for excellence in plumbing, understanding the diverse options available in the market becomes paramount. Service valves come in various forms, each designed to cater to different plumbing applications. With the ever-evolving technology and materials used in their manufacture, the demand for high-quality service valves has surged, making it crucial to stay informed about the best choices available.

In this guide, we will explore the ten best service valves that promise optimal plumbing performance. By examining their features, advantages, and usability, we aim to equip homeowners and plumbing professionals alike with the knowledge needed to make informed decisions, ensuring that plumbing systems run smoothly and efficiently.

Service valves play a critical role in plumbing systems, ensuring efficiency and facilitating maintenance. These valves act as control points within the plumbing infrastructure, allowing homeowners and professionals to isolate specific sections of the system when repairs or inspections are necessary. According to the American Society of Plumbing Engineers, implementing service valves can reduce the time and cost associated with plumbing maintenance by up to 30%, highlighting their importance in a well-functioning system.

Moreover, the proper use of service valves can greatly enhance water conservation efforts. A report by the Environmental Protection Agency emphasizes that targeted maintenance using service valves can help detect and mitigate leaks, which are responsible for wasting approximately 1 trillion gallons of water annually in the United States alone. By allowing for quicker isolation of problematic areas, service valves not only support system longevity but also contribute significantly to overall water efficiency, ultimately playing a vital part in sustainable plumbing practices.

| Valve Type | Material | Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Ball Valve | Brass | 1/2 | 600 | -30 to 200 | Water Supply |

| Globe Valve | Stainless Steel | 3/4 | 800 | -20 to 400 | Steam, Oil |

| Gate Valve | Cast Iron | 1 | 300 | -10 to 200 | Waterworks |

| Check Valve | PVC | 2 | 150 | 0 to 140 | Drainage |

| Pressure Relief Valve | Brass | 1/2 | 150 | -40 to 250 | Safety Systems |

| Ball Cock Valve | Plastic | 3/4 | 100 | 40 to 120 | Toilets |

| Pressure Gauge Valve | Bronze | 1/4 | 400 | -10 to 200 | Hydraulics |

| Strainer Valve | Steel | 2 | 250 | -20 to 200 | Filtration |

| Ultimate Shutoff Valve | Aluminum | 1 | 500 | -20 to 180 | Main Lines |

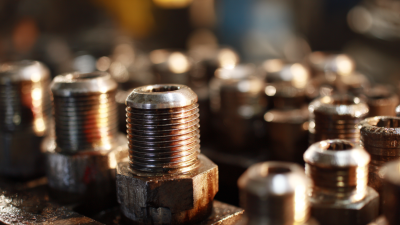

When selecting service valves for optimal plumbing performance, three primary types stand out: ball valves, gate valves, and globe valves. Each type has unique features that suit different plumbing needs and fixture designs.

Ball valves are renowned for their excellent flow control and durability. They consist of a hollow, perforated sphere that allows or blocks flow as it rotates. This design enables quick shut-off and is ideal for applications requiring frequent operation. Additionally, ball valves are less prone to corrosion, making them a long-lasting choice for both residential and commercial settings.

Gate valves, on the other hand, are designed for full flow, minimizing pressure drop when open. They function by lifting a gate out of the path of the fluid. Although they provide efficient flow in a fully open or closed position, they are not suitable for throttling applications, as they can wear over time.

Finally, globe valves offer excellent throttling capability, allowing precise flow regulation. Their unique design creates a longer flow path, which can introduce resistance, but their versatility and effectiveness in controlling flow make them indispensable in many plumbing systems.

When selecting service valves for plumbing systems, it’s crucial to consider various features that can enhance performance and longevity. One key feature to look for is the valve material. High-quality materials, such as brass or stainless steel, offer superior durability and resistance to corrosion, ensuring a longer lifespan even in harsh conditions. Additionally, the valve’s design should facilitate ease of operation, with smooth-turning handles that provide reliable engagement without excessive force.

Another important aspect is the valve type. Ball valves are often favored for their excellent sealing capabilities and low pressure loss, making them ideal for optimal flow control. On the other hand, gate valves might be preferable in systems where minimal flow obstructions are required. Furthermore, the size and compatibility of the valve with existing plumbing infrastructure are essential for maintaining efficiency and preventing leaks. By focusing on these key features, homeowners and professionals can ensure they are selecting the best service valves for their plumbing needs, ultimately leading to improved system performance.

This chart displays the performance ratings of various types of service valves, highlighting their effectiveness in plumbing systems. The rating scale ranges from 1 to 10, with 10 indicating optimal performance.

Service valves play a crucial role in maintaining plumbing systems by ensuring compliance with industry standards and enhancing safety. According to a report by the Plumbing-Heating-Cooling Contractors Association (PHCC), the use of properly installed service valves can reduce the risk of leaks and potential damage by up to 40%. These valves are designed to provide an accessible point for shutting off water supply, which is essential during emergencies or repairs. Compliance with the American National Standards Institute (ANSI) regulations not only guarantees safety but also promotes longevity and efficiency in plumbing systems.

Service valves play a crucial role in maintaining plumbing systems by ensuring compliance with industry standards and enhancing safety. According to a report by the Plumbing-Heating-Cooling Contractors Association (PHCC), the use of properly installed service valves can reduce the risk of leaks and potential damage by up to 40%. These valves are designed to provide an accessible point for shutting off water supply, which is essential during emergencies or repairs. Compliance with the American National Standards Institute (ANSI) regulations not only guarantees safety but also promotes longevity and efficiency in plumbing systems.

Tips: Always choose service valves that meet or exceed ANSI standards. Regularly inspect your valves for corrosion or wear to ensure they function correctly.

Furthermore, incorporating high-quality service valves can significantly improve plumbing system performance. A study published by the International Association of Plumbing and Mechanical Officials (IAPMO) highlights that valves constructed from durable materials, such as brass and stainless steel, can withstand extreme pressures and are less likely to fail. Ensuring your service valves are installed by a certified professional is another pivotal step in meeting regulatory standards while maximizing system safety.

Tips: Consider installing multi-turn valves for greater control over water flow, making it easier to address any plumbing issues promptly.

To ensure the longevity of your plumbing service valves, regular maintenance is crucial. According to a report by the American Society of Plumbing Engineers (ASPE), nearly 25% of plumbing failures are attributed to poorly maintained valves. A simple inspection of the valves every six months can significantly reduce the likelihood of leaks and malfunctions. This includes checking for any signs of corrosion or wear, as these can be indicators that the valve needs to be replaced or repaired.

In addition to regular inspections, keeping the service valves clean is essential. The National Contractor’s Association recommends flushing the valves with clean water and removing any debris that may cause blockages. Utilizing lubricants specifically designed for plumbing applications can also help ensure smooth operation and prevent seizing. By adopting these maintenance tips, homeowners can enhance the performance of their plumbing system and extend the life of their service valves, ultimately leading to a more efficient plumbing environment.