In the ever-evolving world of construction and industrial projects, the right choice of materials can significantly impact the success of your endeavors. Among these materials, "MS pipes" have emerged as a popular choice for many applications due to their durability, versatility, and cost-effectiveness. As we look ahead to 2025, understanding how to select the appropriate MS pipe for your next project is crucial. Leading expert in the field, Dr. John H. Patel, once stated, "The quality and specifications of MS pipes can determine the longevity and safety of any construction project." His insights emphasize the importance of selecting MS pipes that not only meet industry standards but also align with the specific requirements of your project.

Considering factors such as diameter, thickness, and the intended use of MS pipes can be daunting, yet it is essential to ensure optimal performance. Whether you are embarking on a large-scale infrastructure project or a smaller construction task, informed decision-making about MS pipe selection will lead to enhanced efficiency and reliability. In this guide, we will explore the key aspects to consider when choosing the right MS pipe, helping you pave the way for a successful project in the coming years.

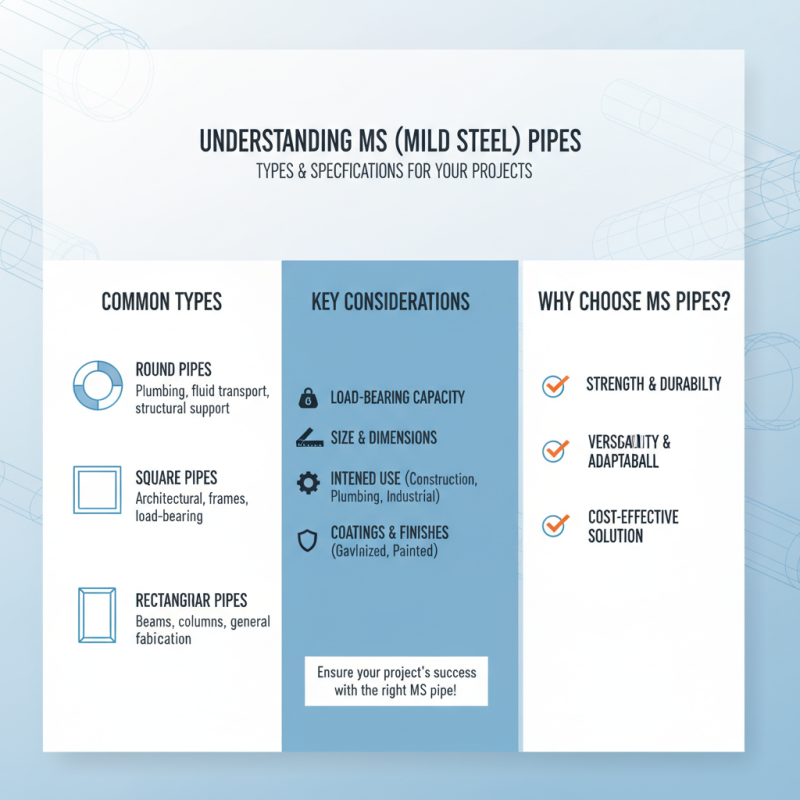

When it comes to understanding MS (Mild Steel) pipes, it is essential to consider the various types and their specifications to ensure they meet the demands of your project. MS pipes are widely used in construction, plumbing, and industrial applications due to their strength and versatility. The most common types include round, square, and rectangular pipes, each serving specific structural and aesthetic purposes. The choice of type depends on factors such as load-bearing capacity, space considerations, and intended use.

Specifications play a crucial role in determining the right MS pipe for your project. Key specifications include wall thickness, diameter, and grade of the steel, which impact the pipe's strength and flexibility. For instance, higher grade MS pipes offer better corrosion resistance and durability, making them suitable for harsh environments. Additionally, understanding industry standards, such as IS 1239 and IS 3589, can assist in selecting pipes that adhere to safety and quality requirements. Evaluating these factors will help you make an informed decision when choosing MS pipes, ensuring they are tailored to the specific needs of your next project.

When selecting MS pipes for construction or industrial projects in 2025, several key factors must be taken into account to ensure functionality, durability, and cost-effectiveness. The first consideration is the application for which the MS pipes will be used. Different projects may require varying pipe specifications, such as thickness, diameter, and resistance to specific environmental conditions. Understanding the intended use will guide the selection process and help in sourcing the most suitable pipes.

Another critical factor is regulatory compliance and standards. In many regions, MS pipes must meet specific industry regulations regarding safety and performance. Ensuring that the chosen pipes comply with these standards not only guarantees quality but also minimizes risks associated with project delays or legal issues. Additionally, examining suppliers' reputations and their offerings in terms of warranties and post-purchase support can significantly influence the decision-making process. As the market continues to expand, particularly in the medical sector where breakthroughs like monoclonal antibodies are on the rise, having robust and reliable infrastructure facilitated by appropriate MS pipe selection becomes even more vital.

When selecting the right MS pipe for your project in 2025, understanding the quality and performance differences among various brands is crucial. According to the latest report by the International Institute of Steel Research, the demand for high-quality mild steel pipes is projected to grow by 6.5% annually through 2026, emphasizing the importance of choosing the right brand. Leading manufacturers like Tata Steel and Jindal Steel are known for their stringent quality control processes, which significantly affect the longevity and reliability of their products.

Additionally, performance metrics such as yield strength and corrosion resistance play a key role in the selection process. Industry benchmarks indicate that top brands achieve an average yield strength of 250 MPa, along with superior resistance to environmental factors, making them preferable for both structural and fluid conveyance applications. A recent study from Market Research Future shows that projects utilizing higher-grade MS pipes experience a 30% reduction in maintenance costs over five years, further highlighting the importance of brand choice in ensuring robust project outcomes.

When it comes to installing mild steel (MS) pipes, understanding the fundamental aspects of installation and maintenance can significantly enhance longevity and performance. First and foremost, proper installation starts with selecting the right fittings and ensuring tight connections to prevent leaks. It’s crucial to clean the pipe ends before assembly to remove any contaminants that could compromise sealing. The use of appropriate jointing methods, whether they are welded, flanged, or threaded, plays a critical role in the structural integrity of the piping system. Additionally, employing suitable protective coatings can help mitigate corrosion, especially in environments prone to moisture.

Maintenance of MS pipes is equally important for ensuring their functionality over time. Regular inspections can identify signs of wear and tear, rust, or other forms of damage that can escalate if left unchecked. Implementing a schedule for cleaning the pipes can prevent the buildup of debris that may obstruct flow. Furthermore, it’s beneficial to periodically check joints and fittings for leaks, tightening them as necessary to maintain a secure connection. By prioritizing these installation and maintenance practices, you can optimize the efficiency and durability of your MS pipe systems in any project planned for 2025.

| Dimension (Diameter) | Wall Thickness | Weight (kg/m) | Application | Maintenance Frequency |

|---|---|---|---|---|

| 20 mm | 2.0 mm | 1.5 | Furniture | Annually |

| 40 mm | 2.5 mm | 3.7 | Construction | Bi-Annually |

| 60 mm | 3.0 mm | 5.2 | Manufacturing | Quarterly |

| 80 mm | 3.5 mm | 6.8 | Water Supply | Semi-Annually |

| 100 mm | 4.0 mm | 8.4 | Oil & Gas | Annually |

As we look ahead to 2025, the manufacturing and usage of MS (Mild Steel) pipes are set to evolve significantly, driven by advancements in technology and sustainability requirements. One of the key trends is the integration of smart technology into pipe production. This includes the adoption of IoT (Internet of Things) devices to monitor the condition and performance of MS pipes in real-time, enabling predictive maintenance and reducing downtime. Such innovations will not only enhance efficiency but also increase the lifespan of pipeline systems.

Moreover, sustainability is becoming a crucial factor in MS pipe production. Manufacturers are exploring environmentally friendly sourcing and recycling processes, aiming to minimize waste and reduce the carbon footprint of their operations. This shift towards green manufacturing practices is likely to influence purchasing decisions, with consumers increasingly favoring companies that adopt eco-friendly methods. Additionally, as industries strive towards achieving net-zero targets, the demand for sustainable MS pipes is expected to rise, shaping the future landscape of construction and infrastructure development in the coming years.