In the ever-evolving landscape of gardening and irrigation, selecting the right hose connector is paramount for ensuring seamless water flow and efficient performance. According to industry expert Dr. Sarah Thompson, a leading horticultural engineer, “A properly chosen hose connector can make the difference between a thriving garden and a frustrating watering experience.” The various types of hose connectors available today offer different features tailored to specific needs, making it essential for users to understand their options fully.

When considering factors such as compatibility, material, and purpose, consumers are better equipped to select a hose connector that meets their individual requirements. Whether you are a professional landscaper or a home gardening enthusiast, the right hose connector not only enhances functionality but also extends the lifespan of your watering system. As we navigate through the important aspects of hose connectors, we will uncover how the right choices can lead to improved efficiency and peace of mind in your gardening endeavors.

When selecting the right hose connector for your needs, it's essential to understand the various types available on the market. The most common connectors include barbed, threaded, and quick-connect options. Barbed connectors are typically used for low-pressure applications and provide a secure fit by using a hose clamp. Threaded connectors, meanwhile, offer the advantage of being easily attached or detached, making them ideal for applications where regular connection and disconnection happen. According to a 2021 report by the Industrial Hose Manufacturers Association, approximately 60% of users prefer threaded connectors for their versatility in varied applications.

Quick-connect fittings have gained popularity due to their ease of use. These connectors allow swift attachment and release, which is particularly beneficial for operations that require frequent changes in equipment. Industry analytics suggest that the demand for quick-connect fittings is projected to grow by 15% annually as more users recognize their convenience in both industrial and household settings.

**Tip 1:** Always consider the pressure rating of the hose and connector to ensure compatibility and safety. Using mismatched components can lead to leaks or failures.

**Tip 2:** When selecting a hose connector, take the diameter into account. Proper size matching can enhance flow efficiency and reduce wear on both the connector and hose.

**Tip 3:** Don’t overlook the material of the connector; choosing corrosion-resistant materials can greatly extend the lifespan of your hose system, especially in harsh environments.

When selecting the right hose connector, several key factors come into play to ensure it meets your specific needs. Firstly, consider the size and type of hose you are using. Connectors come in a variety of diameters and thread types, which must match your hose’s specifications for a secure fit. It’s essential to check the compatibility of the connector with both the hose and the equipment it will be connected to, as mismatched sizes can lead to leaks or inefficient performance.

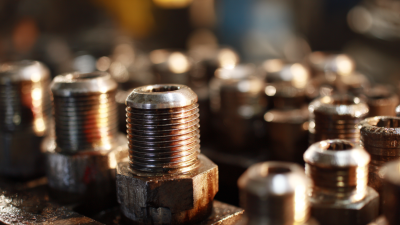

Material is another crucial factor in choosing a hose connector. Common materials include plastic, brass, and stainless steel, each offering different durability and resistance levels to various chemicals, temperatures, and pressure conditions. For instance, if your application involves high temperatures or harsh chemicals, opting for a metal connector might offer better longevity and reliability. Additionally, consider the environment in which the connector will be used; for outdoor applications, connectors with UV resistance or weatherproof features can provide added durability. Taking these factors into account will help you select the best hose connector tailored to your requirements.

| Factor | Description | Recommended Use |

|---|---|---|

| Material | Choose between plastic, brass, or stainless steel based on durability and pressure needs. | Heavy-duty applications require brass or stainless steel. |

| Connection Type | Different connectors such as threaded, push-fit, or quick-connect are available. | Choose based on convenience and type of hose. |

| Size Compatibility | Ensure the connector matches the hose diameter for a secure fit. | Use for standard garden hoses or specialty hoses. |

| Flow Rate | Consider the maximum flow rate your application requires to prevent pressure loss. | Important for irrigation or industrial applications. |

| Ease of Use | Look for connectors that are easy to attach and detach. | Ideal for frequent hose users or DIY projects. |

When choosing the right hose connector, the material is critical for ensuring both durability and performance. Different materials offer various benefits and drawbacks depending on the application. For instance, metal connectors are typically more robust and withstand higher pressures and temperatures, making them suitable for industrial use. In contrast, plastic connectors are lightweight and corrosion-resistant, which makes them ideal for gardening or light-duty household tasks. Understanding the specific environment and conditions in which the connector will be used can help you make an informed decision.

Tip 1: Always consider the fluid being transported. Materials like brass and stainless steel are better suited for liquids that may corrode plastic, while durable plastics can work well with non-corrosive substances.

Tip 2: Look for rubber or silicone seals in connectors, as these can enhance the durability of the connection by providing added resistance against leaks and wear over time. This investment in quality can save you from frequent replacements and repair costs.

By selecting the appropriate material for your hose connector, you can ensure it withstands the test of time while meeting your performance needs. Whether it's for a garden, industrial application, or home use, the right material choice is essential for optimal functionality.

When selecting the right hose connector, the compatibility with various hose and equipment types is paramount. According to a report by the Hose Manufacturers Association, approximately 60% of all hose failures are directly linked to improper connector selection. This underscores the importance of ensuring that your connectors are designed to match the hose's specifications, including diameter, material, and pressure ratings. For instance, whether using PVC, rubber, or thermoplastic hoses, each type requires connectors that can withstand specific chemical and physical stress without degrading.

Compatibility also extends to the equipment with which the hose will be used. A study published by the Industrial Hose Association indicated that mismatched connectors can lead not only to leaks but also to costly downtime and safety hazards. Therefore, it's essential to consider the specifications of the equipment, such as fittings and thread types. For instance, quick-connect adapters are often utilized in pneumatic systems, while barbed fittings may serve better in suction applications. Understanding these distinctions can significantly enhance system efficiency and longevity, ensuring your setup operates seamlessly within its intended parameters.

When it comes to selecting the right hose connector, proper installation and maintenance play crucial roles in ensuring optimal performance. First and foremost, always start with a clean surface to attach the connector. Dirt or debris can cause leaks and hinder the fit. When putting the connector together, make sure to hand-tighten it first, avoiding the use of excessive force, which can damage the thread or the connector itself.

Another important tip for maintenance is to regularly check for signs of wear and tear. Over time, connectors can become brittle or develop cracks, especially when exposed to extreme temperatures or harsh conditions. If you notice any damage, it’s vital to replace the connector immediately to prevent leaks. Additionally, lubricating the threads with a suitable grease can prolong the life of the connection, ensuring a smooth attachment each time.

Lastly, store your hose connectors in a cool, dry place when not in use. Avoid exposing them to direct sunlight or extreme temperatures, which can degrade materials over time. By following these tips for installation and maintenance, you can ensure that your hose connectors perform reliably and effectively for all your needs.