In the realm of plumbing, the selection of the appropriate fittings and valves is crucial for ensuring a reliable and efficient system. According to industry reports, approximately 15-20% of plumbing-related issues can be traced back to inadequate or improper fittings and valves. These components play an essential role in managing water flow, controlling pressure, and preventing leaks, making their correct selection paramount for both residential and commercial projects.

Moreover, the plumbing industry is estimated to be worth over $106 billion in the United States alone, with a significant portion of this expenditure directed towards quality fittings and valves. The importance of these components cannot be overstated, as they must meet various standards for safety, durability, and compatibility with different materials. With the growing emphasis on sustainable practices, plumbing professionals are increasingly focusing on eco-friendly solutions that do not compromise on performance, thereby underscoring the need for informed decision-making in the choice of fittings and valves.

As you embark on your plumbing projects, understanding the specific requirements of your application and the latest industry standards will equip you to make informed choices. Careful consideration of the right fittings and valves will not only enhance the performance of your system but also contribute to long-term reliability and efficiency.

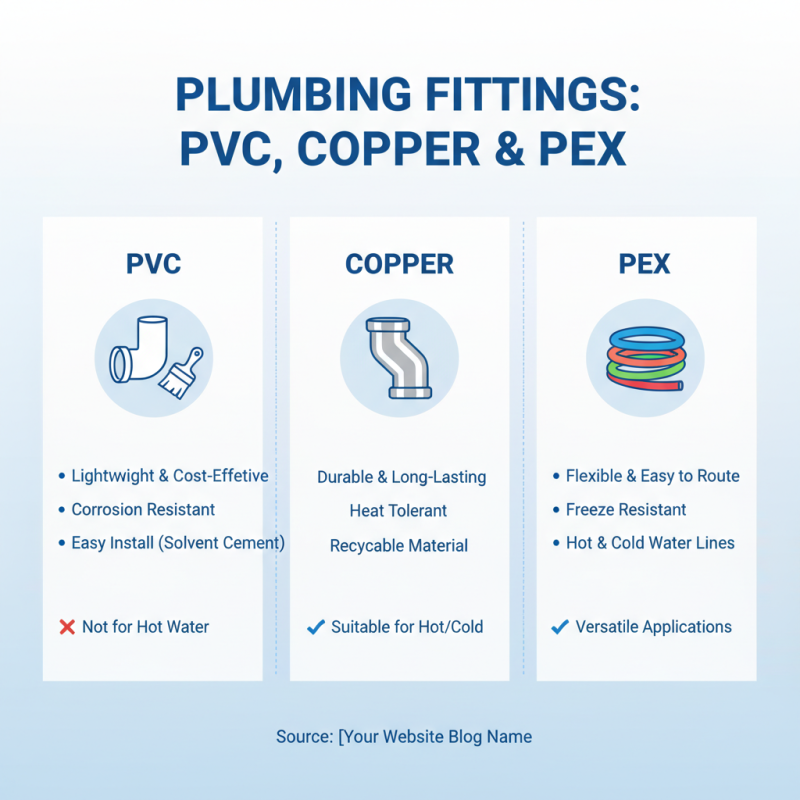

When selecting fittings for plumbing projects, understanding the differences between types such as PVC, copper, and PEX is crucial. PVC, or polyvinyl chloride, is lightweight, cost-effective, and highly resistant to corrosion. This makes it a popular choice for both indoor and outdoor plumbing applications. Its suitability for various pressures and temperatures adds to its appeal, though it is not ideal for hot water lines. Additionally, PVC fittings are easy to install using solvent cement, which can expedite project timelines.

On the other hand, copper fittings are known for their durability and long lifespan. They can handle both high temperatures and pressures, making them suitable for a wide range of plumbing installations, including hot water systems. Copper also has natural antibacterial properties, contributing to healthier water systems. However, the installation process can be more complicated, often requiring soldering, which might pose challenges for DIY enthusiasts.

PEX, or cross-linked polyethylene, has gained popularity due to its flexibility and resistance to scale and chlorine, making it ideal for residential plumbing. It can expand and contract without breaking, reducing the risk of pipe bursts in freezing conditions. PEX fittings can be easily connected with push-fit or crimping methods, offering a user-friendly installation option. Overall, the choice between these materials will largely depend on the specific requirements of the project and personal preferences regarding installation and maintenance.

When selecting valves for plumbing applications, several key considerations must be taken into account to ensure optimal performance and reliability. First, it is essential to identify the specific purpose of the valve within your plumbing system. Different applications, such as controlling water flow, regulating pressure, or preventing backflow, require distinct valve types. For instance, globe valves are ideal for flow regulation, while check valves are crucial for maintaining unidirectional flow in the system.

Another important factor is the material of the valve, which should be selected based on the nature of the medium being transported. Common materials include brass, PVC, and stainless steel, each offering unique benefits such as resistance to corrosion or temperature stability. Additionally, the valve's size and pressure rating must match the plumbing specifications to prevent leaks and ensure system efficiency. Proper sizing is vital, as a valve that is too large may hinder flow control, while one that is too small can lead to pressure drops and increased wear on the system components.

When selecting fittings and valves for plumbing projects, it's important to consider their common usage. This chart illustrates the relative proportions of different types of valves used in plumbing contexts, showcasing the prevalence of ball valves, gate valves, check valves, globe valves, and butterfly valves in various applications.

When selecting fittings and valves for plumbing projects, understanding the impact of pressure ratings is crucial. Pressure ratings indicate the maximum amount of pressure a fitting or valve can safely handle. According to the American Society of Mechanical Engineers (ASME), selecting components with pressure ratings that exceed the maximum expected pressure in your system is essential for ensuring safety and longevity. Standard pressure ratings for plumbing fittings often vary, with PVC and CPVC fittings typically rated between 200-400 PSI, while brass and copper fittings can handle pressures up to 600 PSI or more, depending on thickness and construction.

Another critical aspect to consider is the nature of the fluid being transported through the system. For instance, high-pressure steam systems demand fittings and valves with higher pressure ratings due to the potential for rapid failure if components are mismatched. A report from the American National Standards Institute (ANSI) highlights that improperly rated fittings can lead to catastrophic failures, resulting in project delays and increased costs. Therefore, thorough knowledge of both the environmental conditions and the corresponding pressure ratings will directly affect the performance and reliability of plumbing systems. Properly chosen fittings and valves not only enhance system efficacy but significantly reduce the risk of leaks and failures.

When it comes to plumbing projects, choosing the right fittings and valves is crucial for ensuring a leak-free, efficient system. One of the most vital aspects of this selection process is identifying the correct size for your fittings. Proper dimensions play a significant role in the overall functionality and longevity of your plumbing installation. If the fittings are too large or too small, it can lead to issues like water pressure fluctuations, leaks, or even complete system failures.

Tips: Always measure the pipe diameter before purchasing fittings. Use a caliper for the most accurate measurement, and don’t forget to account for the wall thickness of the pipe. Additionally, when selecting valves, ensure they match the size of the pipes to prevent mismatches that could compromise the integrity of the plumbing system.

Not only does accurate sizing minimize the risk of leaks, but it can also improve the water flow and efficiency of your plumbing system. Over time, improper fitting sizes can lead to increased wear and tear, necessitating costly repairs and replacements. Therefore, taking the time to ensure that all fittings and valves are the correct size not only saves time during installation but also extends the life of the plumbing system.

When selecting plumbing fittings and valves, understanding regulatory standards and certifications is crucial in ensuring quality and safety. Regulatory bodies establish these standards to ensure that plumbing products meet specific performance, durability, and safety criteria. Compliance with these standards is often mandatory, providing a framework that guides manufacturers in the production of reliable fittings and valves. This not only fosters consumer confidence but also enhances overall system functionality, reducing the risk of leaks and failures.

Certification marks, such as those from recognized testing organizations, serve as indicators of quality for consumers and professionals alike. These certifications verify that products have undergone rigorous testing and meet industry benchmarks. It is essential to look for such certifications when selecting fittings and valves, as they help ensure that the components will perform well under pressure, resist corrosion, and endure various environmental conditions. By prioritizing certified products, you contribute to a safer plumbing system that adheres to local and national regulations, ultimately promoting longevity and efficiency in your plumbing projects.