Malleable iron fittings are essential in various industrial applications. They provide strength and versatility, making them a popular choice among engineers. According to a report by the International Iron and Steel Institute, the demand for malleable iron fittings is expected to grow by 4.5% annually through 2026. This trend highlights the increasing reliance on these fittings in construction and manufacturing.

Expert Michael Anderson, a leading figure in the malleable iron industry, states, "Choosing the right malleable iron fittings can significantly enhance the efficiency of your project." His insight emphasizes the importance of understanding the specific requirements of your project. Material quality, size, and compatibility are critical factors. Yet, many overlook these essentials, leading to costly mistakes.

Mistakes can happen. The industrial sector often rushes decisions. Deep research is essential. Quality should never be compromised for short-term savings. Knowledge about malleable iron fittings allows teams to make informed choices. Proper selection can improve performance and longevity in your projects. Balancing cost and quality requires careful thought. Choose wisely.

When selecting malleable iron fittings for your projects, several factors come into play. The application requirements must be clear. Different projects may demand varying levels of strength and durability. For instance, fittings used in plumbing may need to withstand high pressure. Verify the specifications needed for your specific use case.

Another vital consideration is the size and compatibility with existing systems. Mismatched sizes can lead to leaks or structural failure. Take accurate measurements before making a purchase. Remember, purchasing components that fit well is crucial. Sometimes, it’s easy to overlook this, but improper sizing can waste time and resources.

Lastly, be conscious of the finish and coating of malleable iron fittings. Corrosion resistance matters, especially in outdoor or humid environments. Pay attention to coatings that can enhance longevity. It’s tempting to opt for cheaper options, but consider their impact over time. Balancing cost and quality is important; reflect on your project’s long-term needs.

Malleable iron is a unique alloy known for its ductility and strength. It primarily consists of iron, carbon, silicon, and small amounts of other elements. This composition gives it a fine grain structure, making it easy to mold and shape. The presence of carbon allows malleable iron to absorb stress without breaking, which makes it ideal for fittings in various projects.

In construction and plumbing, malleable iron fittings provide durability. They can withstand high temperatures and pressures, making them suitable for demanding environments. However, it’s essential to note that not all fittings are created equal. Variations in manufacturing processes can affect their properties. Some may have imperfections that could compromise performance over time.

When choosing malleable iron fittings, inspect them closely. Look for signs of oxidation or casting flaws. These small details might seem trivial but can lead to significant issues later. Ensuring quality in your selection process is crucial. Always prioritize reliability and functionality in your projects, keeping in mind the environment where these fittings will be used.

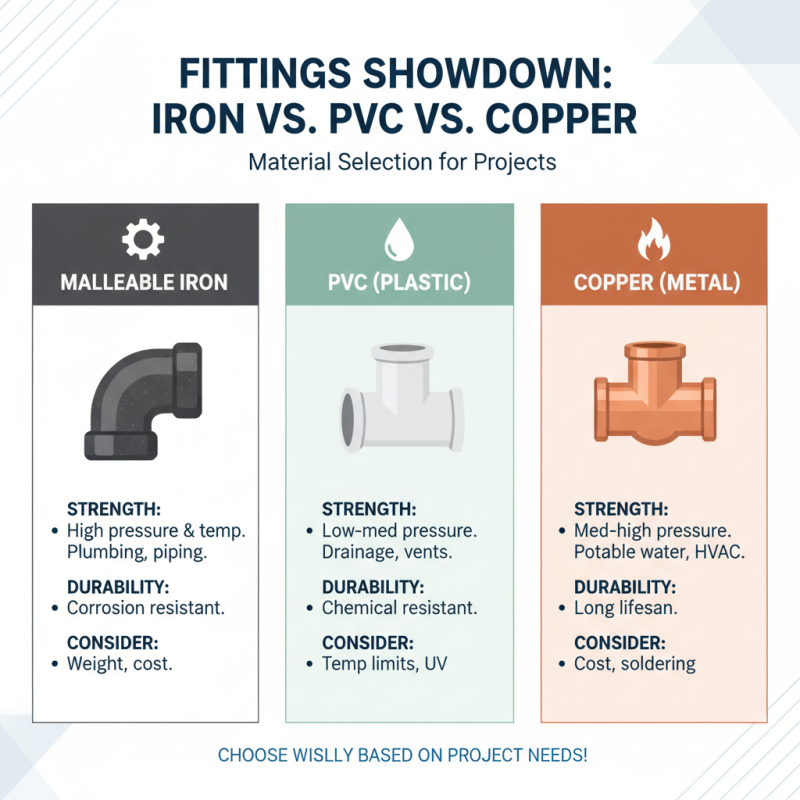

When selecting fittings for your projects, the material plays a crucial role. Malleable iron is known for its strength and versatility. It offers excellent performance in pressure and temperature variations. This makes it a preferred choice for plumbing and piping systems. However, it's essential to compare it with other materials, such as PVC and copper.

PVC fittings are lightweight and resistant to corrosion. They are easy to install but often lack the durability needed for high-stress applications. Copper is strong and has antimicrobial properties, but it can be expensive and requires special tools for installation. Malleable iron strikes a balance between these options, providing robust durability without breaking the bank. It can withstand high pressures better than many alternatives.

Consider the specific needs of your project. Strength, weight, and cost are all important factors. While malleable iron is a popular choice, always remember that each material has its limitations. Reflect on your project's requirements to make an informed decision. Don’t rush—every detail matters.

When selecting malleable iron fittings, industry standards and certifications play a crucial role. In many regions, products must comply with ASTM A47 or ISO 16120 standards. These ensure the fittings are durable and suitable for various applications. According to a 2021 report by the American Society for Testing and Materials, compliance improves product lifespan significantly.

Certifications such as the CE mark in Europe or the ISO 9001 certification indicate a commitment to quality control. Projects using certified malleable iron fittings typically report fewer failures. A lack of compliance can lead to unexpected issues, resulting in costly repairs and delays in construction projects.

Choosing fittings without adequate standards can compromise safety and performance. Even minor deviations in quality can lead to major setbacks. It's essential to verify these standards before making purchasing decisions. Always aim for suppliers who prioritize industry certifications. This approach not only ensures safety but also enhances project integrity.

Malleable iron fittings offer notable cost-effectiveness and longevity, making them an essential choice for various projects. According to industry reports, these fittings can withstand high pressure and temperatures. They are often used in both residential and industrial applications. Their durability reduces the need for frequent replacements, lowering overall costs.

Cost-effectiveness is a significant factor. Studies indicate that malleable iron fittings can last up to 50 years under optimal conditions. This longevity results in less waste and fewer resources spent on replacements. However, initial costs can be higher than other materials. It is crucial to weigh the long-term savings against upfront investments.

Some projects may underestimate installation challenges. Improper installation can lead to leaks and failures, compromising longevity. Regular maintenance is also essential to ensure that these fittings perform at their best. Skipping maintenance can shorten their lifespan dramatically. Therefore, it’s vital to consider not only the initial costs but also the ongoing maintenance needs.