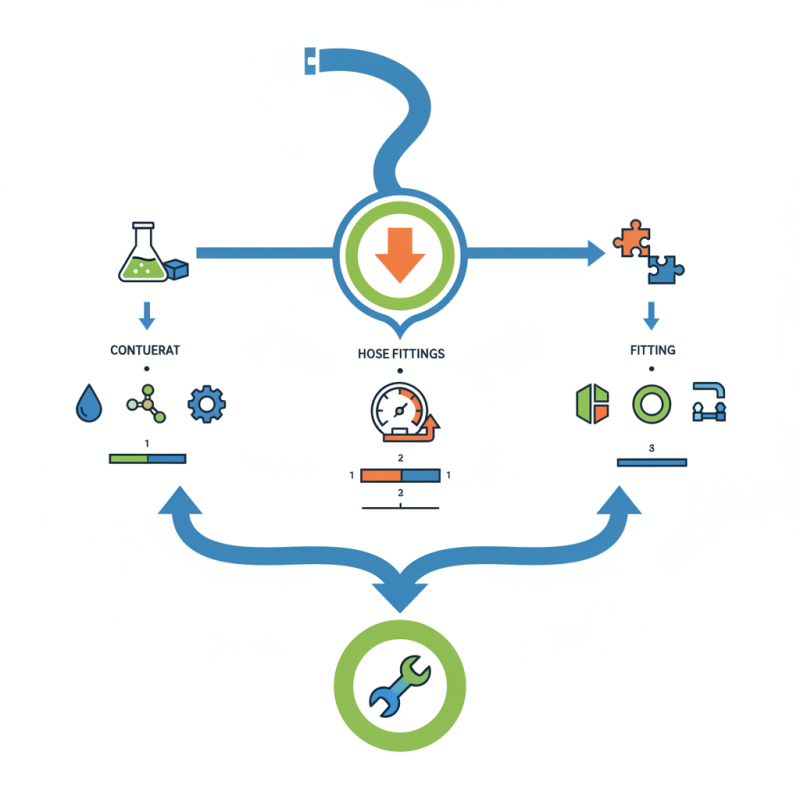

In various industrial and domestic applications, choosing the right hose fittings is crucial for ensuring efficiency and safety. Hose fittings play a vital role in connecting hoses to equipment, facilitating the smooth transfer of fluids and gases. With a plethora of options available, navigating through choices can be overwhelming. Understanding the different types of hose fittings and their specific applications is essential for making informed decisions that meet your unique needs.

When selecting hose fittings, one must consider factors such as material compatibility, pressure ratings, and connection types. This selection process is not only about finding the right fit but also about ensuring durability and performance. Improper fittings can lead to leaks, decreased efficiency, and even hazardous situations. Therefore, it's imperative to assess your requirements thoroughly before making a purchase. By equipping yourself with the right knowledge, you can confidently choose hose fittings that enhance the overall functionality of your system.

Understanding hose fittings is crucial for selecting the appropriate components for any fluid transfer application. Hose fittings come in various types, including barbed, flared, and threaded connections, each serving specific purposes. According to a report by the International Fluid Power Society, the global market for hose fittings is expected to reach $3.2 billion by 2025, driven by the increasing demand in sectors such as agriculture, construction, and manufacturing. Each type of fitting is designed to handle different pressures and fluid types, making it imperative to match the right fitting to the application to ensure safety and efficiency.

In addition to their types, hose fittings also vary significantly in materials, which can affect their compatibility with various fluids and environmental conditions. For example, stainless steel fittings are preferred in corrosive environments, while nylon fittings are often chosen for lighter-duty applications. The Hose Assembly Guideline published by the Hose Manufacturers Association highlights the importance of considering factors such as temperature, pressure, and fluid type when selecting hose fittings. Neglecting these parameters can lead to failures, resulting in costly downtime and repairs, thus underscoring the significance of making informed decisions based on application requirements and industry standards.

When selecting hose fittings, several key factors come into play to ensure you make the right choice for your specific needs. First, consider the material of the fittings. Common options include brass, stainless steel, and plastic, each with its own advantages regarding durability, corrosion resistance, and suitability for different types of fluids. Assessing the environmental conditions where the fittings will be used can help determine the best material—whether they need to withstand extreme temperatures, exposure to chemicals, or harsh outdoor environments.

Another crucial factor is the size and compatibility of the hose fittings with your existing hoses and equipment. Accurate measurements are essential, as mismatched sizes can lead to leaks and system failures. Pay attention to the fitting types: barbed, threaded, or quick-connect options may offer distinct advantages depending on the application. Additionally, it’s vital to evaluate the pressure ratings and flow rates of the fittings to ensure they can handle the demands of your specific setup without compromising performance. By carefully considering these factors, you can select hose fittings that enhance efficiency and safety in your operations.

This bar chart illustrates the importance level (on a scale from 1 to 10) of key factors to consider when selecting hose fittings. Factors include Material, Size, Pressure Rating, Temperature Rating, and Connection Type, which are essential for ensuring that the selected fittings meet the specific needs of your application.

When selecting the right hose fittings, the material choices play a pivotal role in ensuring performance and longevity. The most common materials include brass, stainless steel, plastic, and aluminum, each offering unique advantages. Brass fittings are highly durable and corrosion-resistant, making them suitable for both high and low-pressure applications. In contrast, stainless steel fittings are exceptional for harsh environments, providing enhanced resistance to rust and chemicals.

Tips: When choosing between materials, consider the operating environment of your hoses. If you’re working with water or air, lightweight options like plastic may suffice. However, in applications involving chemicals or extreme temperatures, prioritize metal fittings for their durability.

Also, consider the compatibility of the fittings with your hoses and the fluids being transported. For instance, ensure that the fitting material does not react adversely with the substances in your hoses to prevent leaks or failures. Always consult with a professional for recommendations tailored to your specific needs, ensuring optimal performance and safety in your projects.

| Material | Temperature Range (°C) | Pressure Rating (psi) | Corrosion Resistance | Weight (kg) | Common Applications |

|---|---|---|---|---|---|

| Brass | -20 to 150 | 200 | Good | 0.5 | Water, Air, Gas |

| Stainless Steel | -50 to 200 | 300 | Excellent | 0.8 | Chemicals, Food Processing |

| Aluminum | -40 to 150 | 150 | Fair | 0.4 | General Use, Lightweight Applications |

| Plastic (PVC) | 0 to 60 | 100 | Poor | 0.2 | Drainage, Low-pressure Systems |

| Copper | -10 to 200 | 250 | Good | 0.6 | Plumbing, Heating |

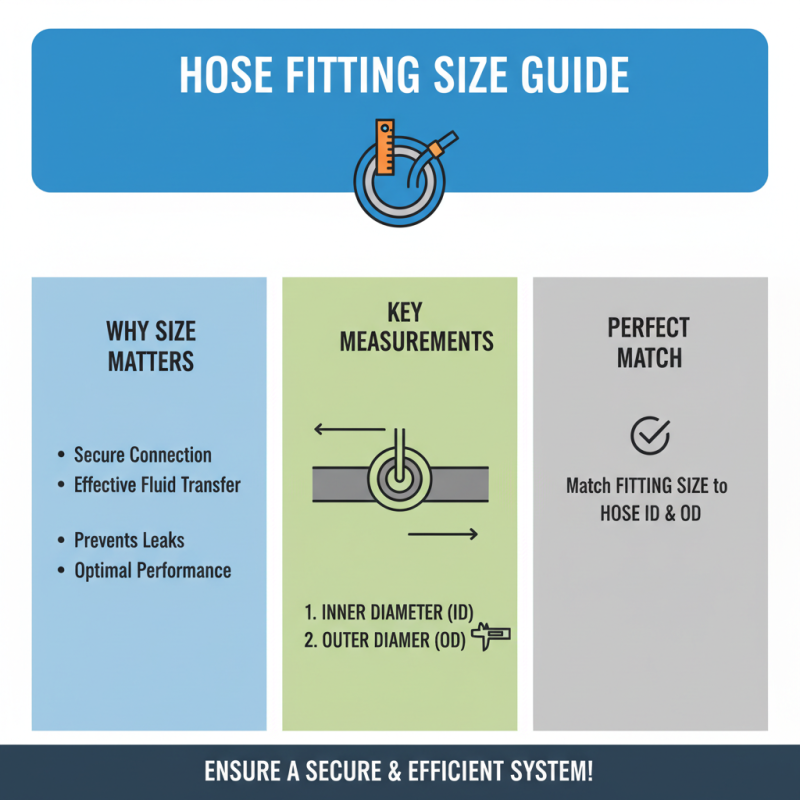

When selecting the right hose fittings for your needs, understanding size requirements is crucial. Hose fittings come in various sizes, and choosing the right one ensures a secure connection and effective fluid transfer. First, measure the inner diameter (ID) and outer diameter (OD) of the hose. This measurement helps identify the fitting size that perfectly matches your hose, preventing leaks and ensuring optimal performance.

In addition to diameter, consider the type of connection your system requires. NPT (National Pipe Thread), BSP (British Standard Pipe), and push-to-connect fittings come in different sizes and styles. Ensuring compatibility between the fitting and your hose, as well as with other system components, is essential. Always refer to manufacturer's specifications for precise measurements and fitting size recommendations to facilitate a smooth integration into your existing setup. By prioritizing proper sizing, you can enhance the reliability and efficiency of your hose system.

When it comes to installing and maintaining hose fittings, several best practices should be followed to ensure optimal performance and longevity. According to industry reports, improper installation can lead to leaks and system failures, which can result in costly downtime. It's essential to inspect all fittings and hoses for compatibility before installation. Matching the materials and sizes appropriately minimizes the risk of failure due to pressure fluctuations and environmental conditions.

Tips: Always use a torque wrench to tighten fittings to the manufacturer's recommended specifications. This prevents overtightening, which can cause damage to both the fittings and hoses.

Regular maintenance is equally critical. A study by the Fluid Power Society indicates that nearly 60% of hose failures are attributed to contamination or wear. To mitigate these risks, establish a routine check-up schedule to clean and inspect hoses and fittings. Look for signs of wear such as abrasions, cracks, or corrosion, and replace any worn components promptly to avoid unexpected failures.

Tips: Implement a logging system to track inspection dates and findings for each hose fitting. This will help maintain a proactive approach to replacements and repairs, ensuring that any issues are addressed before they escalate.