Choosing the right pipe connector for your plumbing needs can be a daunting task, especially with the vast array of options available in the market today. According to John Smith, a plumbing industry expert with over twenty years of experience, "Selecting the appropriate pipe connector can be the difference between a successful plumbing project and a costly disaster." With various materials, sizes, and types to consider, homeowners and professionals alike must be equipped with the right knowledge to make informed decisions.

In plumbing, the role of pipe connectors is pivotal, as they ensure secure, leak-free connections between pipes. Whether you are working on a simple DIY project or a complex installation, understanding the different types of connectors, such as couplings, elbows, and tees, is essential. Each type serves a specific function, and choosing the wrong connector can lead to inefficiencies and potential plumbing failures.

Furthermore, factors such as the materials of the pipes, the environment in which they will be used, and the pressure levels involved all play a critical role in connector selection. By taking the time to consider these aspects carefully, you can choose the right pipe connector that will provide durability and reliability for your plumbing systems, ultimately ensuring peace of mind and longevity in your investments.

When it comes to plumbing, selecting the right pipe connector is crucial for ensuring a secure and leak-free system. Various types of pipe connectors serve different functionalities, making it essential to understand their distinct uses. Common types include threaded connectors, which screw together to form a tight seal, and slip connectors, which are ideal for connecting pipes that are smooth and require a simple push-fit. Additionally, compression connectors utilize a nut and ring to create a secure joint, making them suitable for both rigid and flexible piping.

Tips: When choosing a connector, always consider the material of your pipes. For instance, PVC pipes require specific PVC connectors, while copper pipes need compatible fittings to avoid corrosion issues. Additionally, ensure that the size of the connector matches the diameter of your pipes to prevent leaks.

For more specialized applications, there are also connectors designed for specific tasks, such as T-joints for creating branch connections or couplings for joining two sections of pipe. Depending on your project needs, knowing the purpose of each connector type can greatly enhance the efficiency and reliability of your plumbing system. Always check compatibility with the existing pipes to ensure effective performance.

When selecting the right pipe connector for your plumbing needs, assessing your plumbing requirements and compatibility is crucial. Begin by understanding the specific demands of your plumbing system, which may include factors such as pipe material, diameter, and the types of fluids being transported. Different systems—whether residential or commercial—might have distinct needs; therefore, it’s essential to evaluate the working conditions and pressure levels that the connectors must endure.

Compatibility is another critical aspect to consider. Ensure that the connector you choose matches the materials of the pipes in your system; for instance, using a plastic connector with metal pipes can lead to leakage or corrosion over time. Additionally, take into account the connector’s size and shape to guarantee a snug fit that will maintain the integrity of your plumbing. Consult installation guidelines and consider future maintenance needs, as easy access for repairs can significantly influence the longevity and reliability of your plumbing system.

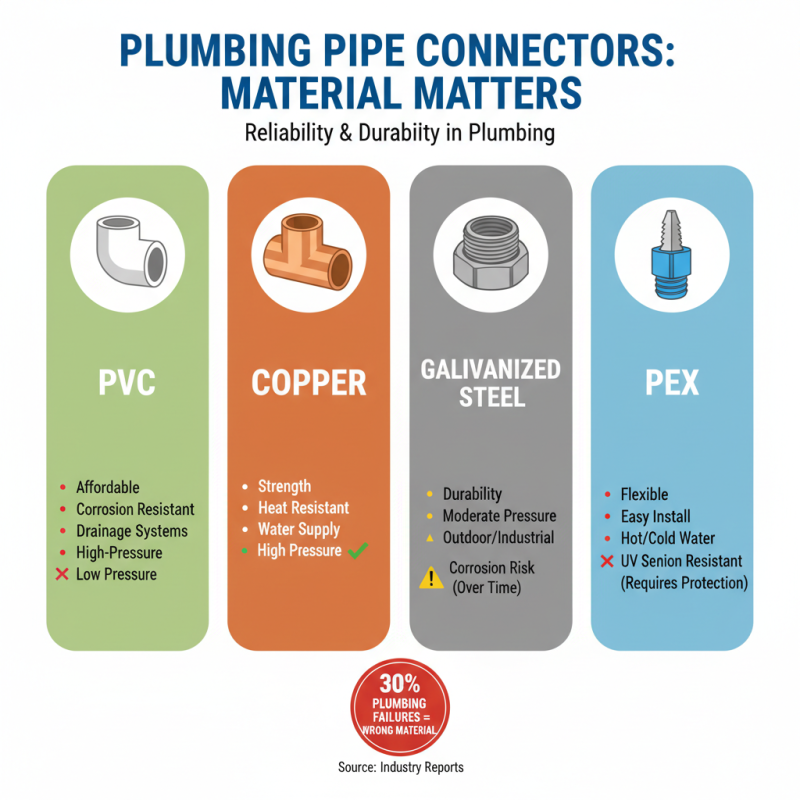

When selecting pipe connectors for plumbing applications, the choice of material is crucial to ensure reliability and durability. Common materials used in pipe connectors include PVC, copper, galvanized steel, and PEX, each offering distinct advantages and drawbacks. According to industry reports, approximately 30% of plumbing failures can be traced back to improper connector material selection, emphasizing the importance of material considerations. For example, PVC is widely used for its affordability and resistance to corrosion, making it ideal for drainage systems. However, it may not withstand high-pressure scenarios, which is where metal connectors like copper excel due to their strength and heat resistance.

Tips: Always assess the specific environmental conditions where the connector will be used. For high-pressure or high-temperature applications, opt for connectors made from durable metals, while plastic connectors can be suitable for low-pressure areas. Additionally, consider the chemical compatibility of the connector material with the fluids it will transport to avoid premature failure.

The longevity of plumbing systems is significantly influenced by material selection. A recent study revealed that using the right material can extend the lifespan of pipe systems by up to 25%. As such, understanding the distinctions between materials not only aids in meeting immediate plumbing needs but also promotes long-term performance. Ensure to evaluate both the operational demands and the physical properties of each material to make informed decisions.

When installing pipe connectors, adherence to best practices is essential for ensuring a secure and leak-free plumbing system. The first step in effective installation involves proper preparation of the pipe surfaces. This means cleaning the edges thoroughly to remove any dirt, grease, or debris that could interfere with the connection. For threaded connectors, applying thread sealant can also help to prevent leaks. Ensuring that the pipes are cut squarely will enhance the fit and allow for a tighter seal, reducing the risk of future issues.

Once the pipes are prepared, aligning the connectors accurately is crucial. Misalignment can lead to increased stress on the connectors and potential failures down the line. When tightening the connectors, it is important to use the right tools and techniques—over-tightening can damage the connectors or the pipes, while under-tightening may lead to leaks. For joint connections, using the correct type of jointing material, such as solder or welding as appropriate, is essential for creating a durable bond. Monitoring for leaks immediately after installation ensures quick identification and rectification of any issues, promoting long-term reliability in the plumbing system.

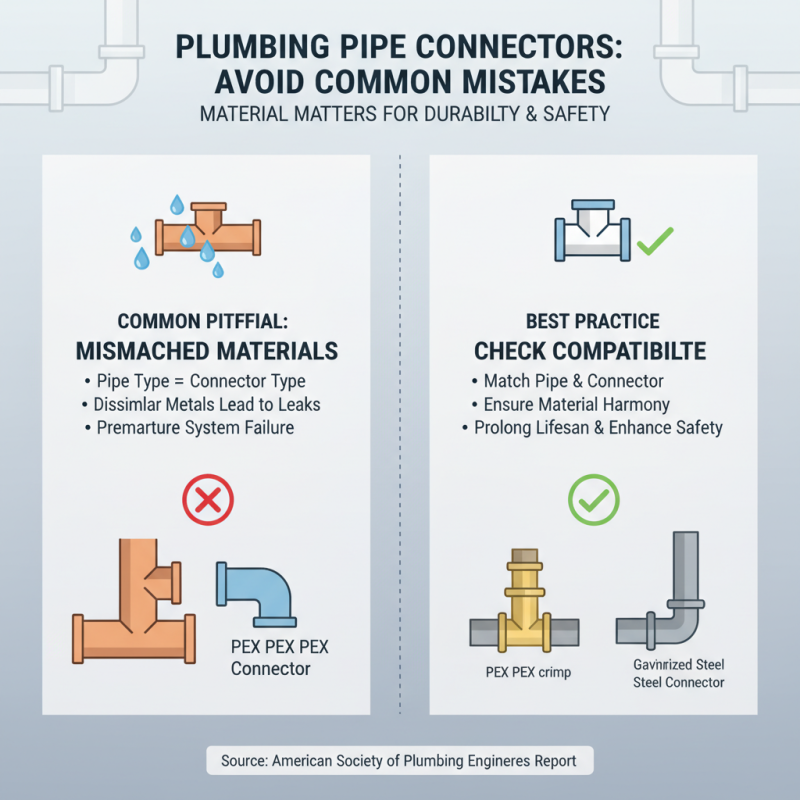

When selecting pipe connectors for plumbing applications, avoiding common mistakes is crucial to ensure both durability and functionality. One of the pitfalls often encountered is failing to accurately match the connector type with the pipe material. According to a report from the American Society of Plumbing Engineers, mismatched materials can lead to leaks and premature failure, particularly in systems employing dissimilar metals. Understanding the compatibility of materials not only extends the lifespan of the plumbing system but also enhances safety and efficiency.

Another frequent error is neglecting to consider the fitting size, which can significantly impact water flow and pressure. A survey by the National Association of Home Builders revealed that improper sizing accounts for over 15% of plumbing issues reported in residential settings. It is essential to measure both the external diameter of the pipe and the internal diameter of the connector to achieve a secure fit. Overlooked details, such as the importance of thread type and sealant application, can also result in leaks and costly repairs. By focusing on these critical aspects, homeowners and professionals can make informed decisions that enhance the overall plumbing integrity.