When it comes to selecting the right DI fittings for your specific applications, the decision-making process can be overwhelming due to the wide variety of options available. DI fittings, or ductile iron fittings, are known for their strength, durability, and resistance to corrosion, making them a popular choice in various industries, including plumbing, construction, and municipal systems. Understanding the critical features and specifications of these fittings is essential to ensure they meet your project's requirements.

In this guide, we will explore essential tips for choosing the appropriate DI fittings that align with your needs. From determining the right size and pressure rating to understanding the different types of coatings and finishes, our tips will help you make informed decisions. By keeping the specific demands of your project in mind, you will be better equipped to select DI fittings that provide optimal performance and longevity, ultimately contributing to the success of your system.

DI fittings, or ductile iron fittings, are essential components in plumbing and piping systems, known for their strength, durability, and resistance to corrosion. These fittings come in various types, each designed for specific applications, such as water transmission, sewage systems, and industrial uses. Common types include elbows, tees, reducers, and flanges, each serving a unique purpose to connect pipes in a reliable manner.

When selecting DI fittings, consider the specific requirements of your project. The first tip is to assess the pressure ratings and temperature limits of the fittings, as these factors significantly impact their performance in different environments. Additionally, review the compatibility of the fittings with the fluids they will handle to prevent any potential chemical reactions that could lead to failure.

Another important tip is to think about installation and maintenance. While DI fittings are robust, opting for products that are easier to install can save time and reduce labor costs. Ensure that adequate sealing options are available, as this can enhance the longevity and efficiency of your piping system. By understanding the different types and applications of DI fittings, you can make an informed decision that suits your specific needs.

| Type of DI Fitting | Material | Common Applications | Size Range (inches) | Pressure Rating (psi) |

|---|---|---|---|---|

| Flanged | Ductile Iron | Water and Wastewater Systems | 4 - 48 | 150 - 300 |

| Bell and Spigot | Ductile Iron | Sewer and Stormwater | 6 - 30 | 250 - 350 |

| Tee | Ductile Iron | Fluid Distribution | 3 - 24 | 150 - 250 |

| Coupling | Ductile Iron | Join Pipes Together | 2 - 36 | 150 - 300 |

| Elbow | Ductile Iron | Change Direction of Flow | 2 - 36 | 150 - 300 |

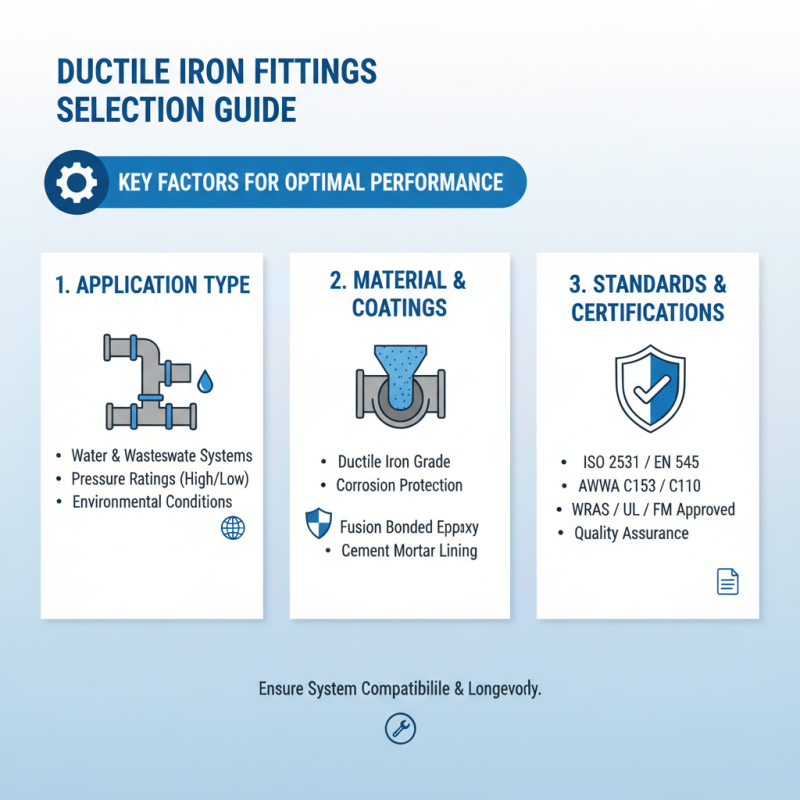

When selecting ductile iron (DI) fittings, several key factors must be considered to ensure optimal performance and compatibility with your systems. Firstly, assessing the type of application is crucial. DI fittings are often used in water and wastewater systems, so understanding the specific requirements of your project—such as the pressure ratings and environmental conditions—will help you choose the most suitable fittings. For instance, fittings designed for high-pressure applications must meet different standards compared to those used for low-pressure systems.

Another important factor is the sizing and compatibility with existing pipes. It is essential to measure the diameter and type of the pipes you will be using to ensure a proper fit with the DI fittings. Incorrect sizing can lead to leaks, reduced efficiency, and potential system failures. Additionally, consider the installation method and whether the fittings will be used in conjunction with other materials. This can influence joint types and sealing methods, so it is vital to check compatibility. By evaluating these factors meticulously, you can select DI fittings that will meet your operational needs and ensure system reliability.

When selecting ductile iron (DI) fittings, understanding material compatibility is crucial. DI fittings are commonly used in various applications, but their performance can vary significantly based on the materials they come into contact with. Chemical reactions, temperature fluctuations, and environmental factors can all affect the integrity of the fittings, leading to potential failures or leaks. Therefore, ensuring compatibility between the DI fittings and the surrounding materials—such as pipes, seals, and coatings—can enhance the longevity and reliability of your system.

One tip for accurately assessing material compatibility is to review the chemical resistance charts specific to the materials involved. These charts provide crucial information about which materials will withstand specific chemicals without degrading. Additionally, considering the operating conditions, including temperature and pressure levels, can guide you in selecting the most suitable fittings. Always consult with manufacturers or professionals who can provide insights based on the actual conditions of your project to avoid costly mistakes.

Lastly, don’t overlook the importance of the installation environment. Factors such as moisture exposure, soil characteristics, and potential external stress should be considered when choosing DI fittings. Using protective coatings or linings can also enhance compatibility and reduce the risk of corrosion. By prioritizing material compatibility, you can ensure that your DI fittings will perform effectively over time, leading to a successful and durable installation.

When installing ductile iron (DI) fittings, proper preparation and methodical execution are key to ensuring longevity and reliable performance. Begin by thoroughly reviewing the manufacturer's guidelines, as they provide essential specifications tailored to the specific fittings being used. Make sure to inspect all components for any signs of damage before installation. Proper alignment is crucial; misaligned fittings can lead to leaks and costly repairs. Utilize proper tools to tighten bolts evenly, and avoid overtightening, which can strain the material and cause fractures.

Maintenance of DI fittings is equally important for their operational efficacy. Regular inspections should be conducted, focusing on joints and connections where leaks are most likely to occur. Look for signs of corrosion or wear, and address any issues immediately to prevent escalation. Additionally, maintaining a clear drainage path around fittings helps to avoid water accumulation, which could accelerate degradation. Educating maintenance personnel on these best practices can substantially increase the lifespan of your DI fittings, ultimately leading to cost savings and reduced downtime.

When selecting ductile iron (DI) fittings, many users inadvertently make mistakes that can lead to costly errors and inefficiencies. One common mistake is overlooking the specific application requirements of their projects. According to industry reports, improper selection of fittings can result in up to a 30% increase in installation costs. This often stems from using fittings that do not meet the necessary standards for pressure ratings or environmental conditions. Ensuring that the selected DI fittings are compatible with system specifications is crucial.

Another frequent error is neglecting the importance of proper sizing. Many professionals assume that standard sizes will suffice for their projects; however, reports indicate that nearly 25% of installation failures are linked to incorrect sizing. This misjudgment can lead to substantial leaks or pressure losses, significantly affecting the overall system performance. It's vital to accurately calculate the flow requirements and to consult engineers or design manuals to guarantee that the fittings chosen are appropriately sized for the intended use, thereby enhancing durability and reliability in the long term.