In the ever-evolving world of construction and plumbing, selecting the right pipes and fittings is crucial for ensuring durability, efficiency, and safety in any project. Expert engineer John Smith, a renowned authority in the pipes and fittings industry, emphasizes, "The right choice of pipes and fittings can make or break the longevity of a system." As professionals face increasing pressures to deliver sustainable and cost-effective solutions, understanding the essential factors in choosing pipes and fittings becomes paramount.

With numerous materials, sizes, and specifications available, making informed decisions can seem overwhelming. Factors such as the environment, pressure ratings, and compatibility with existing systems must be meticulously considered. This is not just about meeting immediate needs; it's about planning for future reliability and compliance with industry standards. As projects grow in complexity, the importance of expert insights cannot be overstated, making this guide to selecting the right pipes and fittings not only timely but essential for professionals aiming to achieve excellence in their work.

When selecting pipes and fittings for your project, understanding the various pipe materials available is crucial. Each material presents its own set of advantages and disadvantages that can significantly impact your project's success. For instance, PVC pipes are cost-effective and resistant to corrosion, making them ideal for drainage systems. However, they may not withstand high temperatures, which can be a concern for hot water applications. On the other hand, copper pipes offer excellent durability and heat resistance but often come with a higher price tag.

Tip: Before making a decision, assess the specific requirements of your project, including variable factors such as temperature, pressure, and the types of fluids being transported. This will help you choose a material that not only fits your budget but also meets your project’s demands effectively.

Another popular choice is PEX tubing, known for its flexibility and ease of installation. PEX is suitable for both hot and cold water systems, but it is important to consider its susceptibility to UV light and certain chemical reactions.

Tip: Always check manufacturer recommendations and ensure compatibility with fittings to avoid costly mistakes down the line. By weighing the pros and cons of each material, you can make an informed choice that best suits your project's needs.

| Material Type | Pros | Cons | Typical Applications |

|---|---|---|---|

| PVC | Lightweight, corrosion-resistant, low cost | Not suitable for high temperatures, can be brittle | Drainage, irrigation, ventilation |

| Copper | Durable, resistant to corrosion, natural antibacterial properties | Expensive, can corrode in acidic water | Water supply, roofing, HVAC |

| Steel | Strong, high pressure tolerance, recyclable | Heavy, prone to rust without coating | Structural applications, plumbing, industrial systems |

| CPVC | Higher temperature tolerance than PVC, corrosion-resistant | More expensive than PVC, requires specific bonding agents | Hot water applications, chlorinated water systems |

| PEX | Flexible, resistant to scale and chlorine, easy to install | Sensitive to UV light, not suitable for outdoor use | Residential plumbing, radiant heating systems |

When selecting pipe diameters for any project, several critical factors come into play to ensure optimal performance and durability. One of the primary considerations is the intended application; for example, high-pressure systems may require thicker walls and larger diameters to withstand the load. Furthermore, industry reports indicate that CPVC pipes, valued at $210 million in 2022, are expected to grow to $350 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 6.5% from 2024 to 2030. This trend signals a growing preference for materials that provide both resilience and versatility in various installations.

Additionally, flow requirements and pressure ratings must be closely examined when choosing the right pipe diameter. Insufficient diameter can lead to increased friction losses and reduced flow rates, adversely affecting system performance. As the demand for CPVC pipes and fittings increases, informed choices about their sizing will be crucial in ensuring efficient and safe operations across industries. Properly sized pipes not only enhance flow efficiency but also minimize maintenance costs and extend the lifespan of the plumbing systems.

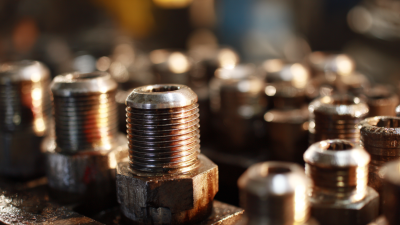

When selecting the appropriate pipes and fittings for your project, understanding the various fitting types is crucial. Each connector has unique properties that make it suitable for different applications. For instance, threaded fittings are excellent for joining pipes where disassembly may be required, while welded fittings provide a secure and permanent bond ideal for high-pressure systems.

One essential tip is to consider the material compatibility between your pipes and fittings. Using fittings made from materials that are not compatible with your piping system can lead to leaks and failures. Another important factor is the pressure rating of the fittings, which should match or exceed the pressure capabilities of your pipes. Always verify that the connectors can handle the intended fluid and environmental conditions to ensure a reliable and safe installation.

When selecting pipes and fittings for any project, understanding pressure ratings and temperature limits is crucial for ensuring durability and reliability.

Pressure ratings indicate the maximum pressure a pipe or fitting can safely handle under specific temperature conditions. Exceeding these limits can lead to catastrophic failures, resulting in costly repairs and safety hazards. It is important to familiarize yourself with the pressure rating system —

typically expressed in pounds per square inch (PSI) — to match your pipeline’s requirements with the appropriate materials.

Moreover, temperature limits play a pivotal role in determining the longevity of piping systems. Different materials respond uniquely to temperature fluctuations; for instance, PVC pipes become brittle in cold conditions while metal fittings may expand under heat.

Knowing the operational temperature range, as well as potential environmental factors, helps in selecting the right materials that won’t compromise the integrity of the system. By critically assessing both pressure ratings and temperature limits, you can ensure that the chosen pipes and fittings will endure the test of time and function effectively in varied conditions.

When it comes to choosing pipes and fittings, the balance between cost and quality is a pivotal factor that can influence the longevity and performance of your plumbing system. Many customers face the dilemma of wanting high-quality materials while remaining within a tight budget. However, making budget-friendly choices doesn't necessarily mean you have to compromise on quality. By researching different materials and understanding their long-term benefits, one can often find cost-effective options that meet both financial constraints and performance expectations.

Investing in higher-quality pipes and fittings can lead to significant savings in the long run. Durable materials like PVC, CPVC, and PEX may have a higher upfront cost but tend to require less maintenance and are less prone to failures compared to cheaper alternatives. Moreover, many reputable manufacturers offer warranties, providing assurance against potential issues. Therefore, analyzing the total cost of ownership rather than just the initial purchase price is crucial for making informed decisions that can prevent frequent replacements or costly repairs down the road.

This chart illustrates the trade-off between cost and average quality ratings for various types of pipes and fittings. It highlights the challenge of selecting products that balance affordability with performance.