In the realm of piping systems, grooved fittings have emerged as a pivotal solution, offering a blend of efficiency and versatility in various applications. According to industry expert Dr. Emily Archer, a leading authority on mechanical engineering, “The adoption of grooved fittings not only enhances the reliability of piping systems but also significantly reduces installation time.” This innovative approach gained traction due to its unique design that allows for quick assembly and disassembly, making it an attractive option for both new installations and retrofitting existing systems.

As industries evolve and the demand for reliable and adaptable piping solutions escalates, the benefits of grooved fittings become increasingly apparent. Their ability to accommodate various materials and pressures, alongside ease of maintenance, positions them as a top choice in sectors such as fire protection, HVAC, and industrial processes. By incorporating grooved fittings, professionals can streamline their operations while ensuring safety and compliance with industry standards.

This comprehensive overview will delve deeper into the benefits, applications, and best practices surrounding the installation of grooved fittings, equipping engineers and technicians with the insights needed to leverage this technology effectively in their projects. From understanding the core advantages to implementing installation tips, this guide aims to enhance the knowledge and application of grooved fittings in modern engineering practices.

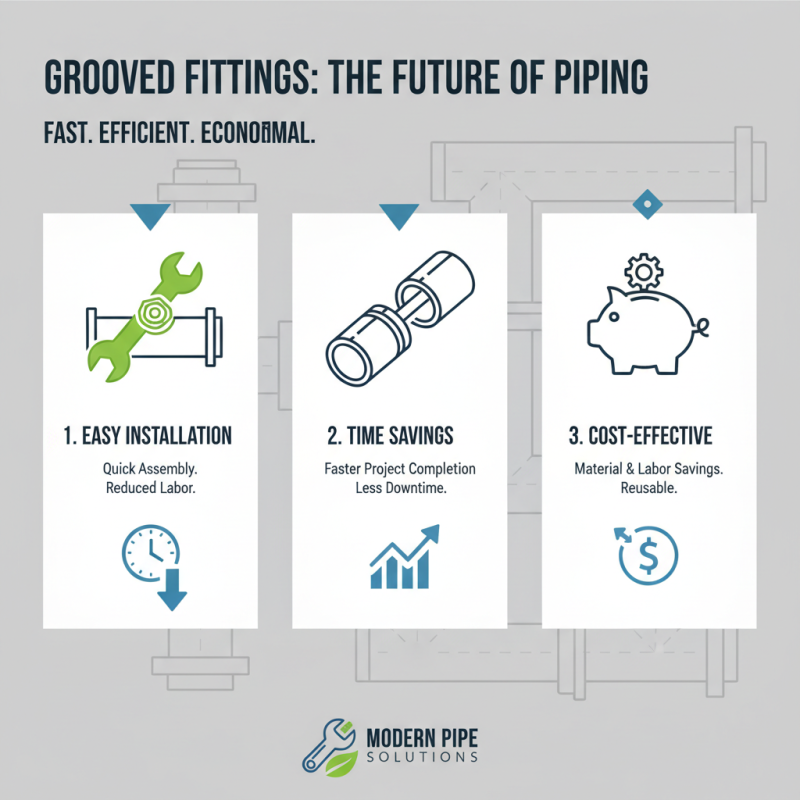

Grooved fittings are gaining popularity in modern piping systems due to their numerous benefits. One of the primary advantages of using grooved fittings is the ease of installation they offer. The design of these fittings allows for quicker assembly and disassembly compared to traditional welding or threaded connections. This not only saves time during installation but also reduces labor costs, making grooved fittings an economically viable choice for many projects.

Another significant benefit of grooved fittings is their ability to accommodate thermal expansion and contraction within piping systems. Their flexible nature allows for movement without compromising the integrity of the connections, leading to enhanced durability and a lower risk of leaks. This feature is particularly beneficial in environments where temperature fluctuations are common, ensuring a longer lifespan for the piping system and reducing maintenance needs.

Moreover, grooved fittings are versatile and can be utilized in various applications, including fire protection systems, HVAC installations, and industrial processes. Their adaptability to different system requirements, combined with their ease of installation and maintenance, makes grooved fittings an attractive option for engineers and project managers aiming for efficiency and reliability in piping infrastructure.

Grooved fittings are versatile components utilized across various industries due to their unique design that facilitates quick and efficient installations. In the construction sector, they are commonly used in piping systems for fire protection, water distribution, and HVAC applications. The ease of connection allows for rapid assembly, which can significantly reduce labor costs and installation time on construction sites. Furthermore, their ability to accommodate thermal expansion makes them ideal for piping systems that require flexibility under varying temperature conditions.

In manufacturing and industrial processes, grooved fittings are essential in facilitating the safe and efficient movement of fluids. They play a crucial role in water treatment plants, chemical processing facilities, and food and beverage production, ensuring a secure and leak-free operation. The robust design of grooved fittings also contributes to the overall durability of these systems, reducing maintenance needs and extending service life.

When installing grooved fittings, there are a few helpful tips to ensure optimal performance. First, always ensure that the pipe ends are clean and free from burrs, as this will enhance the sealing efficiency of the fittings. Additionally, using the correct torque settings during installation will help prevent damage to the components and ensure a reliable connection. Lastly, regularly inspecting the fittings in operational systems can help identify any potential issues early, ensuring long-term reliability and safety.

The installation of grooved fittings is a straightforward process that can significantly enhance the efficiency and durability of piping systems. To begin, ensure that all components, including the pipe, fittings, and grooved couplings, are clean and free of debris. This diminishes the risk of leaks and ensures a secure connection. According to a report by the American Society of Mechanical Engineers, the right preparation can reduce the incidence of installation errors by up to 40%, making it crucial to adhere to these initial steps.

Next, positioning the grooved fitting properly is essential. Align the pipes so that the grooves match perfectly, allowing for a smooth fit. Use a leveling tool to prevent any misalignment, which could cause undue stress on the system and lead to failures over time. Once aligned, install the coupling by sliding it over the grooved area and tightening it according to the manufacturer’s torque specifications. Industry data suggests that properly installed grooved fittings improve flow efficiency by 10% compared to traditional welded fittings, further showcasing their benefits in a variety of applications from fire protection systems to HVAC installations.

| Dimension | Description | Benefits | Common Applications | Installation Tips |

|---|---|---|---|---|

| 2" | Suitable for handling water and other non-corrosive fluids. | Easy installation, lightweight, and cost-effective. | Plumbing and fire protection systems. | Use proper fittings and ensure a good seal. |

| 4" | Ideal for larger pipe systems requiring quick assembly. | Reduces labor costs and time during installation. | Commercial buildings, industrial pipes. | Ensure alignment before tightening. |

| 6" | Designed for high-volume flow systems. | Durable and reliable under varying conditions. | Water supply, HVAC systems. | Use proper tools for tight connections. |

| 8" | Used in extensive piping networks. | Facilitates maintenance and repairs. | Fire suppression and irrigation. | Check for leaks post-installation. |

Maintaining the integrity of grooved fittings is crucial for their longevity and efficient performance in various applications, including HVAC systems and fire protection. According to a report by the American Society of Mechanical Engineers (ASME), regular maintenance can extend the service life of these fittings by up to 30%. To ensure the durability of grooved fittings, it is essential to perform periodic inspections for wear and tear, ensuring that they are free from corrosion and debris that can lead to leaks.

Furthermore, proper lubrication of the grooves is essential; it reduces friction and helps maintain a secure fit between components. The National Fire Protection Association (NFPA) emphasizes the importance of adhering to installation guidelines, as improper installation can lead to significant failures and costly repairs. Implementing a proactive maintenance schedule, which includes visual checks and routine cleaning, will not only enhance the lifespan of grooved fittings but also ensure operational efficiency, ultimately benefiting the overall system design.

When comparing grooved fittings to traditional fittings, several key aspects emerge that highlight their respective advantages and suitability for various applications. Grooved fittings utilize a mechanical joint system that offers ease of installation and flexibility in configuration. This type of fitting allows for faster assembly and disassembly, making it particularly advantageous in situations where maintenance and modifications are frequent. The ability to accommodate slight misalignments and thermal expansions without welding or extensive preparation can lead to significant time and labor savings in construction projects.

On the other hand, traditional fittings, which often rely on welded or threaded connections, can present challenges such as longer installation times, the need for skilled labor, and potential leak points if not executed properly. While traditional fittings may offer a more rigid connection, their susceptibility to failure due to stress and vibration can necessitate ongoing maintenance and inspection. This comparative analysis suggests that while both types of fittings have their applications, grooved fittings tend to offer a more adaptive and user-friendly solution, particularly in fast-paced environments requiring flexibility and efficiency.