MS fittings play a crucial role in construction and industry. These fittings are essential for connecting pipes and tubes. They ensure durability and reliability in various applications. According to Mark Anderson, an expert in industrial fittings, “MS fittings are the backbone of modern infrastructure.” His perspective sheds light on their importance.

In construction, MS fittings are used for structural frameworks. They create strong joints that withstand heavy loads. The quality of these fittings can affect overall project safety. Misalignment or weak connections can lead to costly failures. Industry professionals often emphasize the need for quality assurance.

However, not all MS fittings meet high standards. Some may fail under pressure, leading to significant issues. It's vital for engineers to select the right fittings. The selection process should include rigorous testing. This is essential for ensuring long-lasting and safe installations.

MS fittings, or mild steel fittings, play a crucial role in construction and multiple industries. Their composition primarily includes iron with a minimal carbon content, typically around 0.05% to 0.25%. This low carbon percentage gives MS fittings excellent weldability and malleability. According to various industry reports, these properties make them ideal for various structural applications, spanning from plumbing to structural frameworks.

One notable aspect of MS fittings is their versatility in applications. They are commonly used in piping systems and scaffolding structures. In fact, recent studies indicate that the construction industry alone accounts for about 30% of MS fittings' usage in industrial settings. However, while they are durable, MS fittings are prone to corrosion if not properly treated. This weakness raises questions about their long-term viability in extreme environments.

The manufacturing process of MS fittings involves both hot and cold processing techniques. This variety in processing leads to different performance characteristics. For instance, hot-finished fittings are typically used in high-pressure contexts, whereas cold-finished versions may be adequate for lighter applications. Yet, the inconsistency in quality can sometimes impact their reliability, reminding us to weigh the benefits against potential drawbacks.

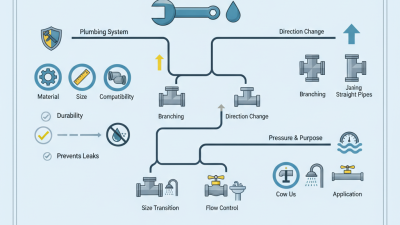

MS fittings are essential components in construction and industry. Various types serve specific purposes. Elbows, tees, and couplings are just a few examples. Each fitting connects pipes or tubes for fluid transport, and they must be chosen carefully.

Elbows allow for directional changes. They come in various angles, like 45 and 90 degrees. Tees create branching points in pipelines, helping to distribute fluids efficiently. Couplings connect two pipe sections securely. The wrong choice may lead to leaks or failures.

Tips: Always check the size and compatibility of fittings. Measure the pipes accurately. Consider the materials used in your environment. Sometimes, imperfections in the assembly process can cause issues. It's crucial to ensure that everything fits snugly. Regular inspections can prevent unexpected problems down the line.

| Type of MS Fitting | Description | Applications | Common Standards |

|---|---|---|---|

| MS Pipe | Mild Steel Pipe used for various applications. | Plumbing, Gas Lines, Structural supports | IS 1239, IS 3589 |

| MS Elbow | Fitting that changes the direction of the piping. | Pipelines, HVAC systems | ASME B16.11 |

| MS Tee | Fitting for branching the flow in a pipeline. | Water supply systems, Oil and Gas | IS 3063 |

| MS Flange | Flat pieces of metal used to connect pipes. | Industrial piping, Machinery | ASME B16.5 |

| MS Coupling | Used to connect two pieces of pipe. | Fluid transport, Chemical processing | IS 1239 |

MS fittings are essential components in construction and industrial applications. Their role in maintaining structural integrity is critical. According to industry reports, the use of quality fittings reduces the risk of structural failure by over 30%. When installed correctly, they can significantly enhance the lifetime of various structures.

However, not all MS fittings perform equally. Some fittings may not meet safety standards, leading to potential hazards. A study highlighted that nearly 20% of fittings on the market do not adhere to established safety protocols. This inconsistency can result in dangerous situations when overlooked.

The correct specifications and installation methods for MS fittings are vital. Inadequate attention to detail can lead to serious consequences. Load-bearing structures rely heavily on these components. Regular inspections can prevent failures. Industry reports show that regular maintenance can extend the life of fittings by 25%. Investing in quality and adherence to safety standards is imperative for long-term safety.

The demand for MS fittings is steadily rising in the global construction sector. These fittings, made from mild steel, are essential for various applications. They connect pipes, tubes, and structures with strength and reliability. Their corrosion resistance adds to their popularity in diverse environments.

Construction projects require durable materials. MS fittings provide the necessary support in frameworks and pipelines. Industries are increasingly integrating them due to their cost-effectiveness and ease of installation. However, there are challenges to consider. Quality variations can impact performance. Not all MS fittings are created equal.

As urbanization continues to grow, the need for efficient infrastructure increases. MS fittings play a crucial role in this process. Builders must pay attention to specifications and standards. Choosing the right fitting can make a difference in long-term durability. This area requires careful planning and selection. Mistakes can lead to significant setbacks in projects.

MS fittings, or mild steel fittings, are widely used in construction and industry. They serve as connectors between pipes and help to create secure and efficient systems. Proper installation is crucial to ensure safety and durability. A common technique involves using Teflon tape on threaded ends to prevent leaks. It's essential to tighten fittings appropriately without overdoing it. Over-tightening can damage threads and lead to future leaks.

Before starting, always inspect the fittings for any visible defects. Avoid using damaged parts, as they can compromise the entire system. Clear the installation area of debris and ensure all components are compatible. It’s advisable to have a checklist of materials before beginning. This prevents last-minute runs to the store, which can delay progress.

During installation, double-check alignment. Misalignments can result in stress on the joints and can lead to premature failure. Record any issues that arise during the process, like unexpected resistance or alignment problems. Documenting these can help improve future projects. Continuous learning from each installation leads to better practices over time. Conversion from theory to practice is often imperfect, and reflection on past jobs is key to mastering the art of fitting installation.