Pipe fittings are essential components in plumbing and construction. They connect different sections of piping and enable fluid flow. Without proper pipe fittings, leaks and pressure issues can occur. These fittings come in various shapes and sizes. Each type serves a specific purpose, ensuring smooth operation.

The concept of pipe fittings may seem simple, yet the details can be intricate. For example, a common type is the elbow fitting. This allows pipes to change direction seamlessly. Understanding these details is crucial for effective installation. A minor error can lead to significant problems later.

While the function of pipe fittings is clear, their selection can be challenging. Choosing the right material is vital. Certain materials endure better under pressure or temperature changes. Reflecting on these choices can prevent future headaches. Ultimately, a thorough understanding of pipe fittings enhances system reliability.

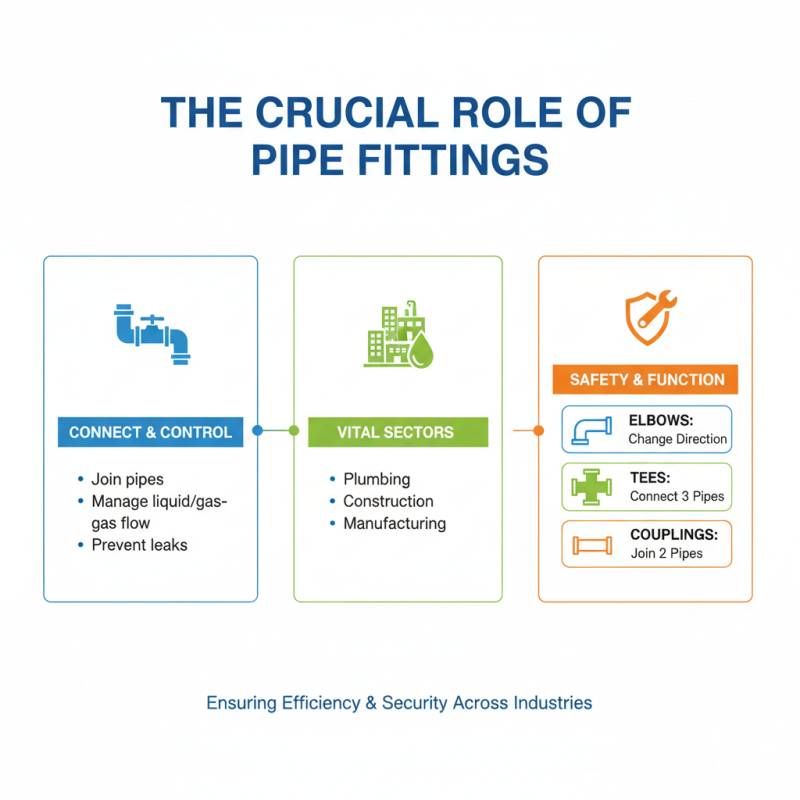

Pipe fittings play a crucial role in various industries. They connect pipes and control the flow of liquids or gases. This makes them vital in plumbing, construction, and manufacturing sectors. Also, they help prevent leaks and ensure safety. Different types of fittings serve unique purposes. Elbows change flow direction, tees connect three pipes, and couplings join two.

Choosing the right fitting requires careful consideration. Factors like material, size, and pressure rating matter. Mistakes can lead to system failures. For example, using a fitting rated for low pressure in a high-pressure system can be disastrous. Additionally, improper installation may cause leaks or bursts.

Understanding the specific needs of a project is essential. Each industry has unique standards and requirements. Some may prioritize durability, while others focus on cost-effectiveness. The selection process isn't always straightforward. Industry professionals often debate over the best options. Balancing quality and budget is a challenging task.

Pipe fittings play an essential role in connecting various pipes. They come in diverse shapes and materials, serving different functions. Common materials include PVC, copper, and stainless steel. Each material has its own benefits and drawbacks. PVC is lightweight and easy to install but may not withstand high temperatures.

When it comes to shapes, a few main types stand out. Elbows change the direction of flow, while tees create a branch. Couplings connect two pipes of the same diameter, and reducers join pipes of differing sizes. Each fitting type is crucial for specific applications and projects. However, choosing the wrong type can lead to leaks or system failures.

Understanding the various types and materials can be challenging. Sometimes, professionals overlook important details. For instance, not considering temperature variations could be risky. Proper selection ensures durability and efficiency in plumbing systems. A comprehensive overview aids in making informed decisions. Crafting successful installations requires careful thought and attention to detail.

| Type of Pipe Fitting | Material | Shape | Applications |

|---|---|---|---|

| Elbow | PVC | 90-degree angle | Water drainage systems |

| Tee | Stainless Steel | T-shaped | Fluid transport |

| Coupling | Brass | Straight | Connecting two pipes |

| Union | Copper | Threaded design | Temporary connections |

| Cap | Plastic | Closed end | Ending pipe runs |

Pipe fittings play a crucial role in plumbing and HVAC systems. They connect pipes and facilitate fluid transfer. According to industry reports, an estimated 20% of plumbing failures stem from improper fittings. These failures result in costly water damage and repairs. Fittings like elbows, tees, and couplings are essential for navigating complex layouts. They allow for bends and changes in direction, ensuring efficient flow.

In HVAC systems, pipe fittings contribute to airflow management. They help in connecting ducts and managing temperature control. For instance, a well-designed duct system can improve energy efficiency by up to 30%. However, using incorrect fittings can cause leaks. These leaks can lead to significant energy loss and increased utility bills.

Tips: Always choose the right fitting for your specific application. Verify compatibility with the pipe material. Regularly inspect fittings for signs of wear or damage. It can save you from unexpected expenses. Remember, small issues can lead to big problems over time. Addressing them early is vital.

Pipe fittings are essential components in plumbing and piping systems. They facilitate the connection of pipes, allowing for changes in direction, size, or flow of liquids and gases. Understanding the standards and specifications that govern these fittings is crucial for ensuring reliability and safety in various applications.

The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) play key roles in setting these standards. ANSI outlines the dimensional standards for fittings, ensuring compatibility across different manufacturers. ASTM focuses on the performance and testing methods, ensuring that materials withstand specific pressures and temperatures. These standards not only guide manufacturers but also help engineers make informed choices.

Reflecting on these standards, we often find discrepancies in compliance among various suppliers. This inconsistency can lead to unexpected challenges. For instance, using fittings that don’t fully meet ANSI standards may result in leaks or failures. It is essential to stay informed and advocate for quality when selecting pipe fittings. Understanding the complexities of these specifications can lead to better decision-making and improved project outcomes.

This chart represents the various types of pipe fittings used in construction and plumbing, categorized by their standard specifications according to ANSI and ASTM. Each type of fitting plays a crucial role in ensuring the integrity and efficiency of piping systems.

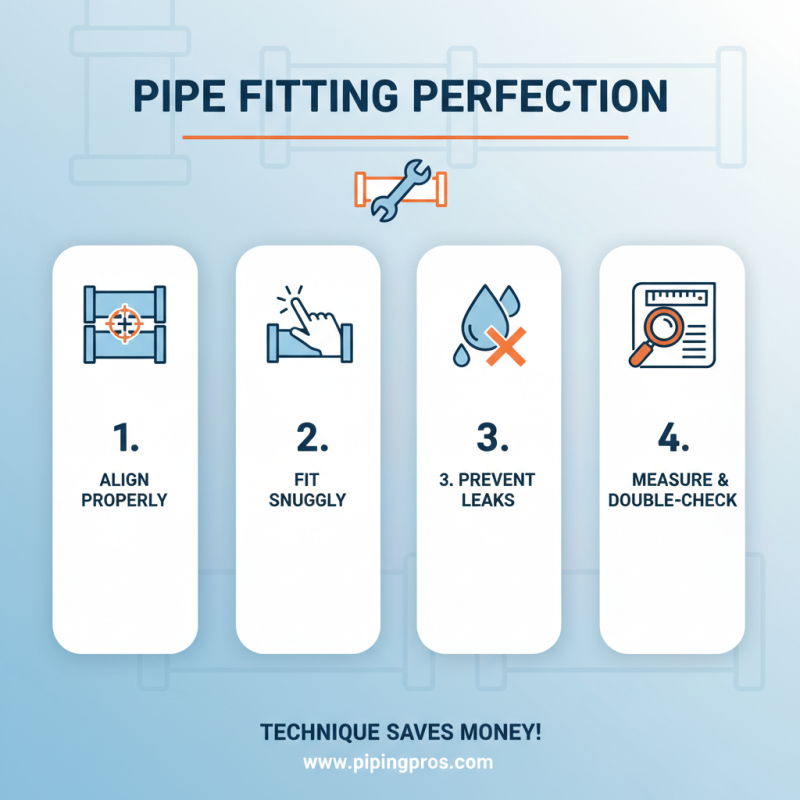

When it comes to installing pipe fittings, technique matters. Proper alignment is crucial. Pipes should fit snugly into the fittings. If they are even slightly misaligned, it can lead to leaks. Take your time to measure accurately. Double-checking your work can save you from costly mistakes later.

Using the right tools is equally important. Wrenches should be used carefully to avoid over-tightening. This can damage the fittings and create gaps. It’s helpful to practice on scrap pieces first. Messing up a fitting can be frustrating, but it’s part of learning. Note that not all fittings are designed for the same pressure levels.

Incorporating support systems can aid in stability. Brackets or clamps can help hold pipes in place. This reduces wear and tear over time. Always assess your work area. Look for potential hazards that could complicate the installation. No installation is perfect; small errors can creep in. Reflecting on these aspects can improve future projects.