In the intricate landscape of plumbing systems, understanding the function and importance of service valves is crucial for both homeowners and plumbing professionals alike. According to industry expert John Smith, "Service valves are the unsung heroes of plumbing; they provide essential control and maintenance access that can save time, money, and even prevent property damage." This statement underscores the pivotal role that service valves play in ensuring the integrity and efficiency of plumbing installations.

Service valves, often overlooked, are key components that facilitate the regulation of water flow and enable maintenance procedures without disrupting the entire system. They provide essential access points for repairs, replacements, and routine servicing, which help extend the lifespan of plumbing infrastructure. By strategically placing service valves throughout plumbing systems, professionals can efficiently manage water supply and minimize potential disruptions.

As we explore the functionality and application of service valves, it becomes evident that they are integral not only for maintaining operational efficiency but also for safeguarding public health and comfort. Whether in residential settings or commercial buildings, service valves are indispensable tools that empower plumbers to effectively manage water systems while ensuring safety and reliability.

A service valve is a critical component in plumbing systems, acting as a control mechanism for water flow. Typically installed on water supply lines, these valves provide a way to isolate parts of the plumbing system for maintenance or repairs without having to shut off the entire water supply. They are especially useful in both residential and commercial settings, where changes to water pressure and flow can occur due to various activities such as system checks or fixture replacements.

According to industry standards, service valves are essential for ensuring the longevity and efficiency of plumbing systems. The Plumbing-Heating-Cooling Contractors Association (PHCC) highlights that having properly functioning service valves can reduce the risk of water damage and leaks during maintenance tasks, which can lead to costly repairs. In fact, studies indicate that proactive plumbing maintenance, including regular checks of service valves, can save homeowners and businesses approximately 10-15% in overall plumbing costs annually.

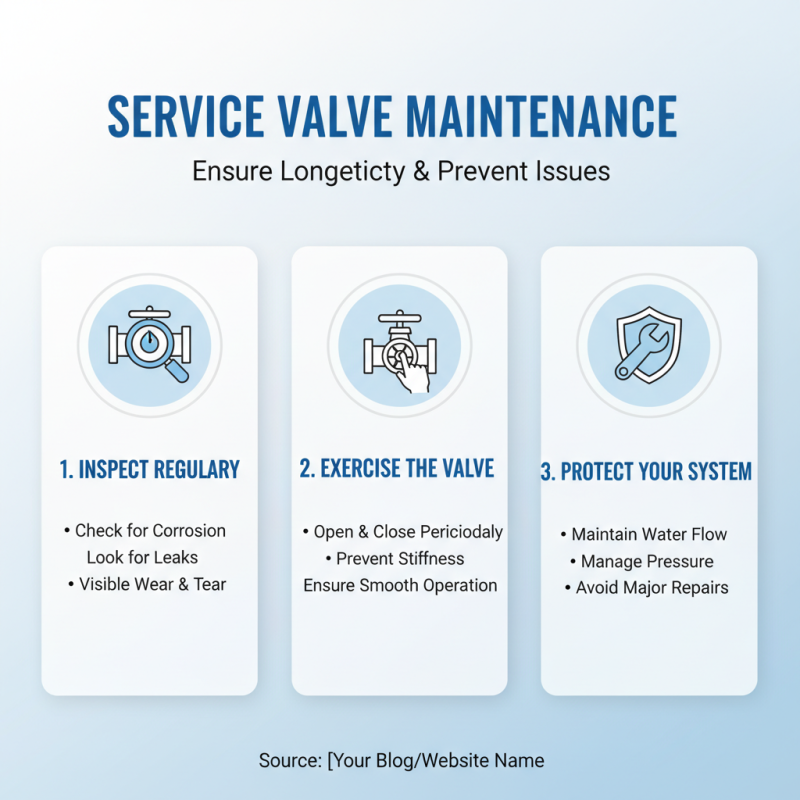

Tip: Regularly inspect your service valves for signs of wear or corrosion, and ensure they are easily accessible for quick service. This simple maintenance step can help maintain efficient plumbing operation.

It is also advisable to familiarize yourself with the operation of your service valves. Knowing how to swiftly shut off this valve in an emergency can prevent extensive water damage, saving both time and resources. Additionally, consider scheduling annual plumbing checks to assess the condition of these vital components, ensuring they function correctly when needed.

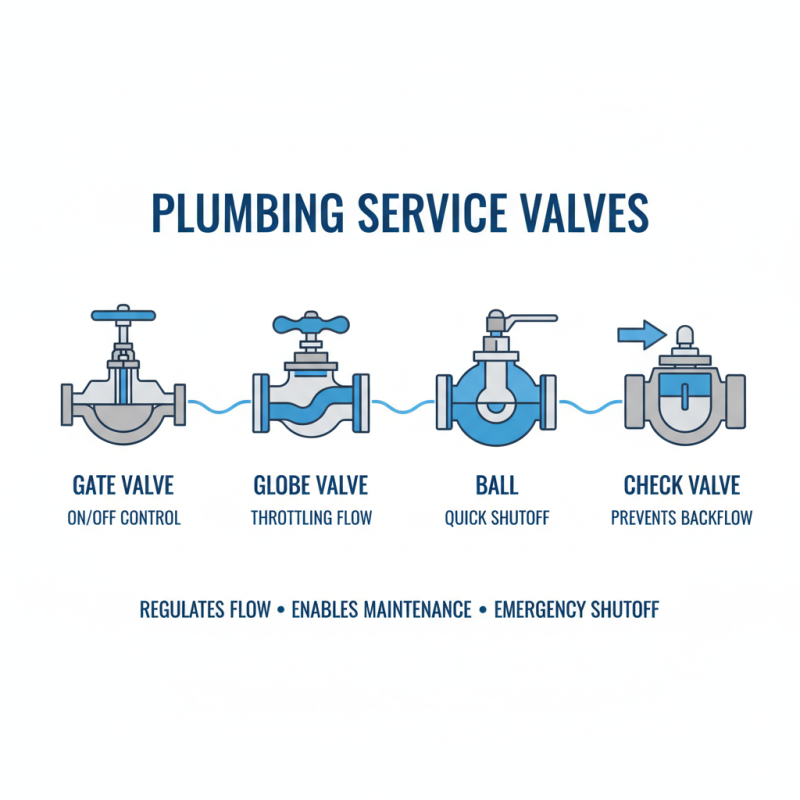

Service valves play a critical role in plumbing systems by regulating the flow of water and allowing for maintenance and emergency shutoff. There are several types of service valves, each designed for specific applications. The most common types include gate valves, globe valves, ball valves, and check valves. Gate valves are typically used for on/off control, while globe valves are better suited for throttling flow. Ball valves provide a quick shutoff, making them ideal for situations where immediate flow control is needed. Check valves, on the other hand, prevent backflow, ensuring that water flows in one direction only.

When choosing a service valve, consider the system's requirements, such as pressure ratings and media type. Installation location is also crucial, as some valves are better suited for indoor or outdoor use.

Tips: Always ensure that the valve is easily accessible for maintenance and emergency situations. Regularly check the functionality of your service valves and replace any that show signs of wear or corrosion to maintain the efficiency of your plumbing system. Keeping a log of when maintenance is performed can help track the lifespan and service needs of each valve in your system.

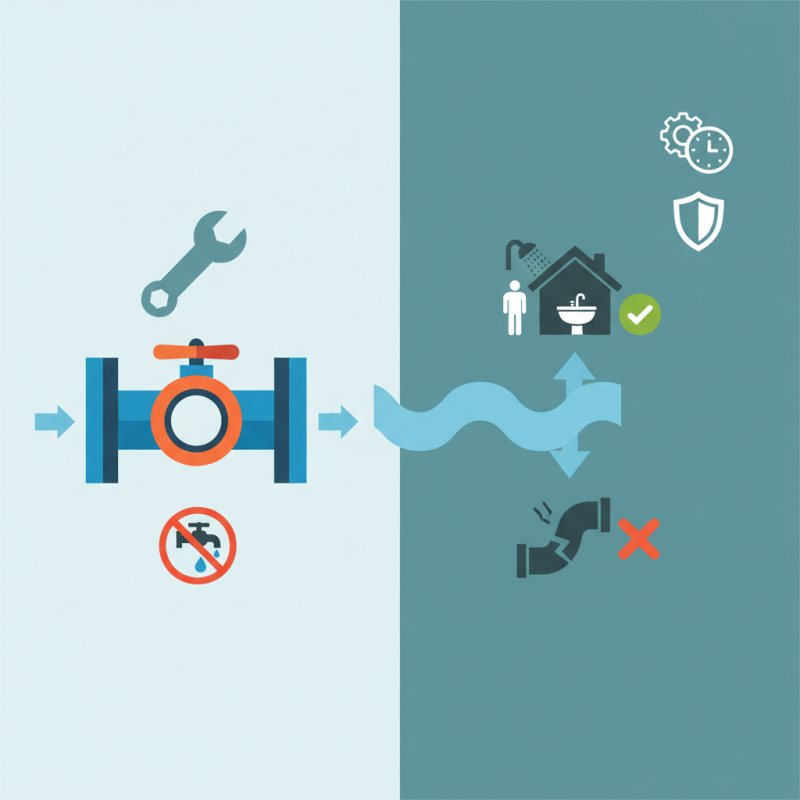

Service valves play a crucial role in plumbing installations by controlling the flow of water through pipes. These valves are strategically placed within the plumbing system to allow for easy access to the water supply. By turning the valve, homeowners or plumbers can quickly stop the flow of water to certain fixtures or sections of the plumbing system without affecting the entire system. This capability is essential not only for repairs and maintenance but also for routine inspections.

When service valves operate within plumbing installations, they typically feature a straightforward mechanism that involves a rotating handle or lever. When turned one way, the valve remains open, allowing water to flow freely; when turned in the opposite direction, it closes and halts the water supply. This operation is vital during emergencies, such as leaks or burst pipes, as it minimizes water damage and makes repair efforts more manageable. Additionally, service valves must be regularly maintained to ensure proper functionality, preventing issues such as rust or blockage that could impede their operation.

Service valves play a crucial role in plumbing systems, providing essential control over water flow in residential and commercial properties. One of the most significant benefits of using service valves is the ability to isolate specific sections of a plumbing system for maintenance or repair. For instance, if a leak occurs, a service valve allows plumbers to quickly shut off water supply to the affected area without disrupting the entire system. According to the American Society of Plumbing Engineers (ASPE), a well-designed plumbing system incorporating service valves can reduce repair times by up to 40%, minimizing both water damage and associated repair costs.

Additionally, service valves contribute to improved system efficiency and longevity. By controlling water flow effectively, these valves can help eliminate excess pressure that might lead to pipe bursts or other failures. A report from the Plumbing Manufacturers International (PMI) indicates that plumbing systems with properly installed service valves experience fewer outages and extended lifespans, thereby reducing the frequency of costly replacements. The strategic use of service valves can also facilitate better water conservation efforts by allowing for targeted repairs and maintenance, ultimately leading to more sustainable plumbing practices.

| Dimension | Details |

|---|---|

| Definition | A service valve is a type of valve used in plumbing systems to control the flow of water. |

| Types | Ball valve, gate valve, and globe valve are common types of service valves. |

| Function | Used to stop or regulate the flow of water for maintenance and repair of plumbing fixtures. |

| Location | Typically installed near water supply sources, such as at the water meter or at individual fixtures. |

| Benefits | Facilitates easy maintenance, prevents water damage, enhances system efficiency, and provides emergency shut-off capabilities. |

| Installation | Should be installed by a qualified plumber to ensure proper function and prevent leaks. |

Service valves play a crucial role in plumbing systems, acting as control points for water flow and pressure management. Regular maintenance of these valves is essential to ensure their proper function and longevity. Inspecting the valves for signs of wear, such as corrosion or leaks, can help prevent more significant plumbing issues down the line. It’s advisable to periodically exercise the valve by opening and closing it to keep the mechanism free from stiffness and ensure it operates smoothly when needed.

Troubleshooting service valves typically involves checking for common problems such as leaks or valve failure to open or close properly. If a leak is detected, tightening the packing nut may resolve it, but in cases of severe corrosion or damage, replacement may be necessary. For valves that resist movement, applying a lubricant can ease the operation, but one must be cautious to not use excessive force, which could lead to more significant damage. By staying vigilant and performing routine checks, homeowners can avoid disruptions and maintain an efficient plumbing system.