In the realm of fluid transfer systems, the significance of hose fittings cannot be overstated. As industry expert John Thompson, a leading authority in fluid mechanics, once stated, "The right hose fittings are essential for maximizing efficiency and ensuring a leak-free operation." This statement encapsulates the vital role that hose fittings play in various applications, from industrial machinery to gardening setups.

With the proper knowledge and selection of hose fittings, users can enhance performance and simplify installation processes across diverse environments. Understanding the types and specifications of hose fittings is crucial for anyone looking to optimize their fluid systems. In our Top Hose Fittings Guide, we will delve into the essential factors that contribute to effective hose fitting performance, ensuring that both professionals and DIY enthusiasts can achieve seamless connections and reliable operations. By following this comprehensive guide, you will gain insights into the best practices for choosing and installing hose fittings for optimal results.

Hose fittings are essential components in hydraulic and pneumatic systems, ensuring secure connections between hoses and equipment. Understanding the various types of hose fittings is crucial for optimal performance in applications ranging from gardening to industrial machinery. Common types include barbed fittings, which provide excellent grip on the hose, and threaded fittings, which allow for a tight seal. Compression fittings and quick-connect fittings are also popular for their convenience and ease of disassembly, making them ideal for situations where hoses need to be frequently swapped or maintained.

When selecting hose fittings, consider the specific application requirements such as pressure ratings and fluid compatibility. Using the right fitting not only enhances performance but also minimizes the risk of leaks and failures. It's important to ensure that the fitting size matches the hose diameter and that materials used are suitable for the working environment.

Tips: Always check the manufacturer's specifications and recommendations before purchasing hose fittings. This can save you time and resources by ensuring you acquire the appropriate components for your needs. Additionally, regular inspections of hose fittings can help identify wear and tear early, preventing costly downtime and maintaining system efficiency.

| Type of Hose Fitting | Material | Application | Pressure Rating | Connection Type |

|---|---|---|---|---|

| Barbed Fitting | Plastic / Brass | General Purpose | 150 psi | Hose Clamp |

| Compression Fitting | Brass / Stainless Steel | Hydraulics | 300 psi | Threaded |

| Quick Connect | Aluminum / Plastic | Pneumatics | 150 psi | Push-to-Connect |

| Camlock Fitting | Aluminum / Stainless Steel | Chemical Transfer | 250 psi | Cam Lock |

| Swivel Fitting | Brass / Nylon | Automotive | 200 psi | Threaded |

When selecting hose fittings, several key features should be prioritized to ensure both optimal performance and hassle-free installation. One critical consideration is the material of the fittings. Common materials include

brass,

stainless steel, and

plastic, each offering unique advantages. For instance, according to a report by the

American Society of Mechanical Engineers (ASME), stainless steel fittings are known for their resistance to corrosion and high temperatures, making them ideal for industrial applications where durability is crucial.

Another important factor is the compatibility of the fittings with the hose and the work environment. It's essential to consider the hose diameter, pressure ratings, and the chemical compatibility of the fitting material with the conveyed media. The

Fluid Power Journal highlights that incorrect fitting choices can lead to leaks or failures, which in turn can affect system reliability and efficiency.

Furthermore, installation ease can be enhanced by selecting fittings with features such as quick connect designs or those that allow for tool-free assembly, thus minimizing downtime and labor costs.

Finally, the sealing mechanism of the fittings should be assessed. Fittings with O-rings, for example, provide better sealing under pressure, reducing the risk of leaks. The

National Fluid Power Association (NFPA) states that ensuring a proper seal can enhance system performance, leading to lower maintenance costs and increased operational lifespan. By focusing on these key features, users can significantly improve the effectiveness and reliability of their hose fittings.

When it comes to hose fittings, ensuring a proper installation is essential for optimal performance and longevity. According to the Fluid Power Journal, nearly 30% of hydraulic system failures can be traced back to improperly installed fittings. This statistic highlights the importance of following a meticulous step-by-step installation process to avoid leaks, pressure drops, and unintended operational interruptions.

Firstly, it is crucial to choose the right fitting for your specific hose type and application, as mismatched fittings can lead to significant operational inefficiencies. According to the Hose and Coupling Manufacturers Association, proper sizing and selection can improve flow rates and reduce energy consumption by as much as 15%. Once you have selected the appropriate fitting, the next step involves preparing your hose by cutting it to the correct length and ensuring the cut is clean to facilitate a secure connection. Employing a hose cutter rather than a standard blade can enhance accuracy and prevent fraying.

In the installation phase, it is essential to firmly yet carefully attach the fitting to the hose. Ensure the fitting is inserted fully into the hose to achieve a proper seal, and use the right tools for tightening; do not overtighten, as this can weaken the fitting or hose. According to research by the American National Standards Institute, following the manufacturer's guidelines for torque specifications can enhance the durability of your connection and significantly reduce the likelihood of leaks over time. By adhering to these best practices in hose fitting installation, users can significantly improve system reliability and performance.

Proper maintenance is essential for enhancing the performance of hose fittings. Regularly inspecting fittings for signs of wear and damage can prevent leaks and ensure a tight seal. Look for cracks, corrosion, or any buildup of debris that may impair functionality. A clean and well-maintained fitting not only extends its lifespan but also ensures optimal fluid flow, minimizing pressure drops that could affect system efficiency.

In addition to visual inspections, lubricating the threads of fittings can significantly improve their connection ease and reduce wear during disassembly. It’s recommended to use a compatible lubricant that is safe for the fluid the hose is conveying. Furthermore, always ensure that the fittings are tightened to the manufacturer’s specifications to prevent loosening over time, which can lead to leaks and performance issues. By following these maintenance tips, users can achieve reliable operation and extend the service life of their hose fittings.

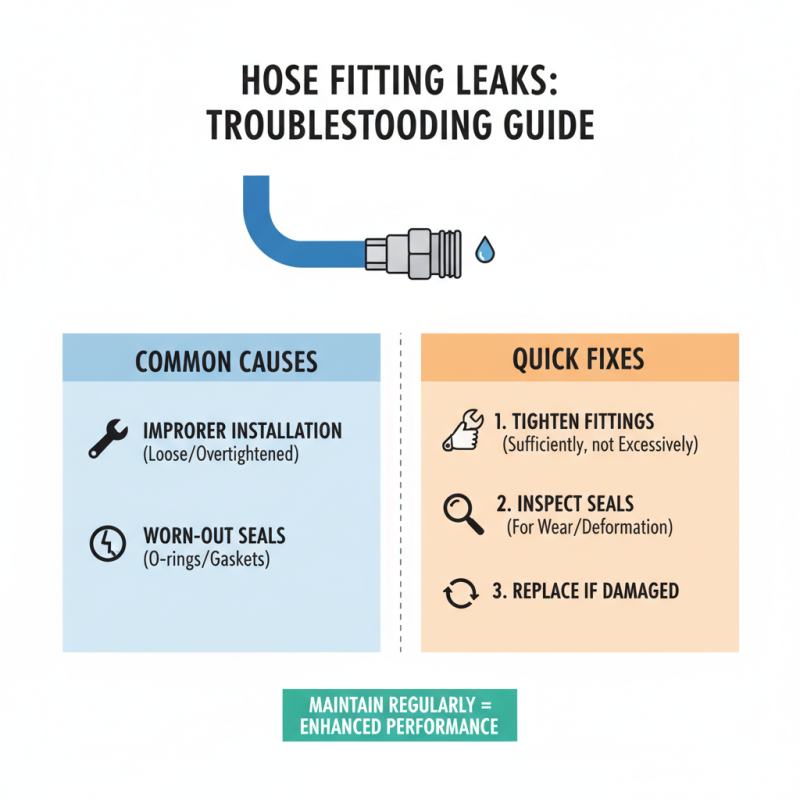

When working with hose fittings, it's not uncommon to encounter issues that can disrupt the normal flow of operations. One of the most frequent problems is leaking connections. This often arises from improper installation or worn-out seals. To troubleshoot, first ensure that the fittings are tightened sufficiently, but not overly so, as over-tightening can damage the threads. If the leak persists, inspect the O-rings and gaskets for any signs of wear or deformation, and replace them if necessary. Regular maintenance of these components will enhance performance and extend the lifespan of the fittings.

Another common issue involves compatibility between hose and fitting sizes. Using mismatched fittings can lead to instability during operation, resulting in potential hazards. To address this, always verify that the hose diameter corresponds correctly to the fitting size. Additionally, check for any obstructions within the hose that could affect flow. Implementing a systematic approach to selecting fittings can make a significant difference in both functionality and safety. By staying attentive to these common issues, users can ensure that their hose fittings perform optimally and efficiently.