In recent years, the plumbing industry has seen a significant shift towards grooved pipe fittings. According to the 2022 Global Plumbing Solutions Report, the use of these fittings has increased by 30% over the last five years. This trend highlights their efficiency and ease of installation. Industry expert Dr. Emily Carter emphasizes this, stating, "Grooved pipe fittings provide an unmatched combination of speed and reliability."

These innovative fittings simplify the connection process. They reduce installation time and material costs, making them a preferred choice for many plumbing projects. For instance, projects utilizing grooved fittings often require approximately 25% less labor compared to traditional fittings. However, some professionals argue that improper installation can lead to issues. It’s crucial for plumbers to be well-trained in this area to avoid costly mistakes.

Despite the advantages, the grooved pipe fittings market can be challenging. Resources are sometimes scarce, and not every supplier offers the same quality. As we move towards 2026, it’s vital to continuously assess the effectiveness of using grooved pipe fittings in plumbing solutions. This reflection will help us ensure we maximize the benefits while minimizing risks.

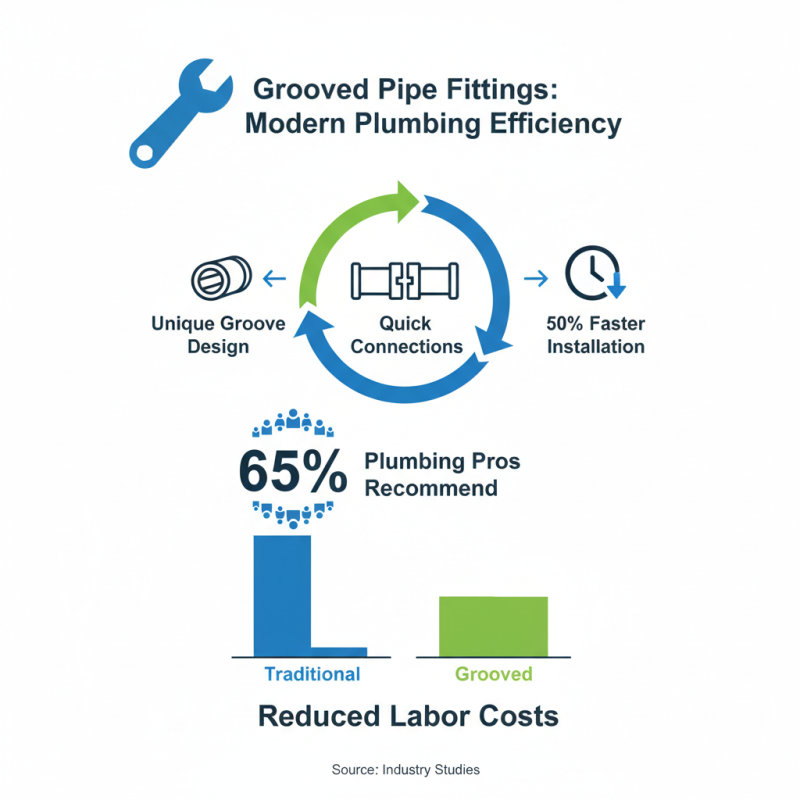

Grooved pipe fittings have gained popularity in modern plumbing for their efficiency and reliability. These fittings utilize a unique groove design that allows for quick connections, reducing installation time by up to 50%. In busy construction environments, this time-saving feature can significantly lower labor costs. According to industry studies, over 65% of plumbing professionals recommend grooved fittings for their ease of use.

The advantages extend beyond installation. Grooved fittings offer flexibility in system design, accommodating movement and expansion. This flexibility can lead to fewer leaks and lower maintenance costs. Research indicates that systems using grooved fittings show a 30% reduction in failure rates compared to traditional methods. However, not all projects may benefit equally. Conditions must be assessed closely; improper installation can compromise performance.

It's important to note that while grooved fittings enhance efficiency, they are not a one-size-fits-all solution. Certain environments may require more traditional fittings for optimal results. Understanding the specific needs of a plumbing system is crucial. Ultimately, choosing the right fittings is about balancing efficiency, cost, and the unique requirements of each project. This complexity underscores the necessity of careful planning and installation by professionals.

Grooved pipe fittings are becoming a popular choice in plumbing solutions. They facilitate quick assembly and disassembly. This flexibility is crucial in many industries. A report by the American Society of Plumbing Engineers noted that nearly 35% of plumbing professionals preferred grooved fittings for their ease of use.

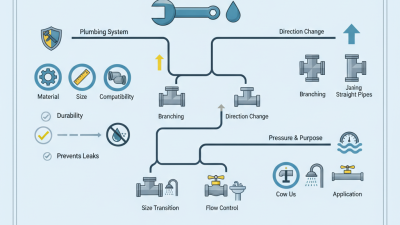

Various types of grooved pipe fittings exist. The most common include couplings, elbows, tees, and reducers. Couplings connect two pipes efficiently. Elbows help navigate around obstacles. Tees enable branching off, and reducers change pipe sizes. Each fitting serves a unique role, yet even experienced plumbers can struggle with proper selection. Misuse or misunderstanding of these fittings can lead to leaks and increased costs over time.

The installation process can also pose challenges. A study highlights that 40% of plumbers encounter installation errors. Common issues include misalignment and insufficient tightening. These mistakes can compromise the system's integrity and function. Proper training and understanding of each fitting type are critical for avoiding these pitfalls. Without clear knowledge, one's efficiency could easily diminish.

When installing grooved pipe fittings, attention to detail is crucial. These fittings allow for quick assembly and disassembly. According to a recent industry report, grooved systems can reduce installation time by up to 30%. Efficiency is key in plumbing, and this method streamlines the process.

Start by selecting the appropriate size of grooved fittings for your project. It’s essential to ensure a snug fit. Over-tightening can lead to damage, while under-tightening may cause leaks. Studies indicate that improper fittings account for 15% of plumbing failures. Therefore, take this step seriously.

When joining pipes, clean the surfaces thoroughly. Dirt and debris can affect the seal. Utilize lubricants where necessary to ease assembly. Always check for proper alignment. Misalignment can result in performance issues. In certain scenarios, an ill-fitted joint could also lead to costly repairs. Aim for precision with every installation, as even small errors can have significant consequences.

| Step | Description | Tools Required | Safety Precautions |

|---|---|---|---|

| 1 | Prepare the workspace by ensuring all necessary materials are at hand. | Pipe cutter, grooved fittings, wrench | Wear safety goggles and gloves. |

| 2 | Cut pipes to the desired length using the pipe cutter. | Pipe cutter, measuring tape | Ensure cutter is sharp to avoid splintering. |

| 3 | Deburr the edges of the cut pipes to ensure a smooth fit. | Deburring tool | Keep hands away from cutting edges. |

| 4 | Fit the grooved fittings onto the ends of the pipes. | Grooved fittings | Check for proper alignment of fittings. |

| 5 | Secure the fittings using appropriate clamps and bolts. | Wrench, clamps | Tighten bolts gradually to avoid over-tightening. |

| 6 | Inspect the installation for leaks and proper fit. | Visual inspection | Observe for any sign of leaks. |

Grooved pipe fittings are a popular choice for plumbing systems. They offer quick installation and reliable connections. However, maintaining these fittings is crucial for long-term efficiency. Regular inspections can help identify issues early. Make sure to check for leaks and corrosion frequently.

Tips: Inspect the grooves for debris. Clean them gently to ensure a proper seal. Use a simple cloth and mild cleaner. Avoid harsher chemicals that could damage the fittings. Keep an eye on connections, especially at bends and joints.

Proper lubrication can extend the life of grooved fittings. Use a recommended lubricant that minimizes wear. Over time, fittings may loosen. Tightening them might be necessary. However, over-tightening can lead to cracks or misalignment. Observe the installation guides closely but don't hesitate to seek advice when uncertain.

Grooved pipe fittings are widely used across various industries. They provide a reliable solution for fluid transport in many applications. In commercial buildings, these fittings help connect piping systems seamlessly. Their design allows for quick installation and easy disassembly. This can save time during repairs or upgrades.

In the HVAC industry, grooved fittings are essential. They connect pipes for heating and cooling systems. This connection method minimizes leaks, enhancing energy efficiency too. Additionally, in the fire protection sector, these fittings are vital for sprinkler systems. They allow for flexible pipe routing, adapting to complex layouts without compromising safety.

While grooved fittings offer advantages, some might overlook their limitations. They may not suit every application. For instance, in high-pressure systems, other fittings could perform better. Understanding when to use grooved fittings is crucial. Regular maintenance checks can help identify wear and potential failures over time. It's a reminder to reassess and reflect on the choices made in plumbing solutions.